TM-5-2350-262-20-3 - Page 62 of 319

TM 5-2350-262-20-3

3-27

•

Stop engine; relieve hydraulic pressure.

Remove all test equipment and connect

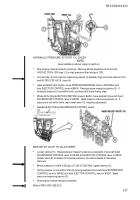

HYDR FLTR-IN-13R hose (1) to high-pressure filter inlet port 13R.

.

•

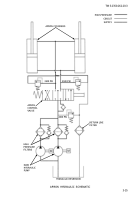

Connect tee (2) and pressure measuring device (3) between high-pressure inlet port 13L

and HYDR FLTR-IN-13L hose (4).

•

Have assistant start engine, move SPRUNG/UNSPRUNG lever to SPRUNG, and

hold EJECTOR CONTROL lever in BACK.

Read pressure measuring device (3).

If

hydraulic pressure is not within limits, continue with the following step.

•

While still holding EJECTOR CONTROL lever in BACK, have assistant move left-hand

SUSPENSION CONTROL lever to RAISE.

Read pressure measuring device (3).

If

pressure is not within limits, main relief valve 13L requires adjustment.

•

Release EJECTOR and SUSPENSION CONTROL levers.

•

Loosen jamnut (5).

Read pressure measuring device as assistant moves left-hand

SUSPENSION CONTROL lever to RAISE and EJECTOR CONTROL lever to BACK.

Rotate valve (6) clockwise to increase pressure; counterclockwise to decrease

pressure.

•

When pressure is 3,950-4,050 psi (27,235-27,925 kPa), tighten jamnut (5).

•

Verify pressure is now within limits by having assistant move left-hand SUSPENSION

CONTROL lever to RAISE and hold EJECTOR CONTROL lever in BACK.

Read

pressure measuring device (3).

•

Stop engine; relieve hydraulic pressure.

Refer to TM 5-2350-262-20-2.

HYDRAULIC PRESSURE AT PORT 13L CHECK

NOTE

Have suitable container ready to catch oil.

MAIN RELIEF VALVE 13L ADJUSTMENT

Back to Top