TM-5-3805-254-14-P-2 - Page 498 of 894

TRUCK SERVICE MANUAL

FUEL SYSTEM

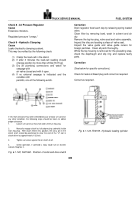

Check 5 - Loose Or Broken Plunger, Coupling Swage

Joint

Cause

Coupling not swaged deep enough into plunger.

Wrong spring used.

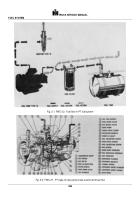

Check 6 - Excessive Link Wear

Cause

New link placed in old socket.

5/16 inch [7.94 mm] link turned end for end at time of

assembly.

Check 7 - Bright Polished Spots At Top And Bottom

Of Plunger 180 deg.

Apart

Cause

Bearing pattern on plunger.

Correction

Attempt to rotate by hand-replace if defective.

J and C injector springs could be mixed with PT (type D)

springs.

PT (type D) springs are 1/16 inch [1.59 mm]

longer, have 0.187 inch [4.75 mm] diameter wire with a

slightly larger O.D.

Correction

Mark links when removed.

Part number should be installed in up position.

Correction

This is normal wear.

Unless metal is displaced or wear

is measurable, plunger may be reused.

493

Back to Top