TM-5-3990-263-13-P - Page 489 of 728

FIELD MAINTENANCE

CENTER ROLLER HYDRAULIC SYSTEM REPAIR

INITIAL SETUP:

Tools and Special Tools

Pan, Drain, 5-Gallon (WP

0078, Table 2, Item 1)

Tool Kit, General Mechanics: Automotive

(WP

0078, Table 2, Item 2)

Materials/Parts

Rag (WP

0081, Table 1, Item 21)

Lockwasher (WP

0082, Table 1, Item 42) Qty:

1

Lockwasher (WP

0082, Table 1, Item 50) Qty:

2

Lockwasher (WP

0082, Table 1, Item 43) Qty:

2

O-ring (WP

0082, Table 1, Item 21) Qty:

1

Lockwasher (WP

0082, Table 1, Item 41) Qty:

2

References

Parts Manual (WP

0073, Figure 4)

References (cont.)

Parts Manual (WP

0073, Figure 8)

Parts Manual (WP

0073, Figure 22)

Parts Manual (WP

0073, Figure 23)

WP

0038

Equipment Condition

Load removed from the BAP. (WP

0008)

BAP unloaded from the CBT. (WP

0006)

REMOVAL

NOTE

Use a drain pan to catch fluid draining from hoses and fittings. Wipe up any spillage with a

rag. Handle, store, and dispose of drained fluids in accordance with local policies and

procedures.

1.

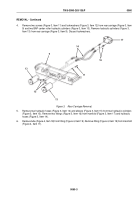

To relieve pressure from center roller hydraulic system, move hydraulic hand pump selector lever (Figure 1,

Item 1) down, in TRANSLOAD position, and pump hand pump lever (Figure 1, Item 2) until two transload

cylinders (Figure 1, Item 3) are fully extended.

TM 5-3990-263-13&P

0060

0060-1

Back to Top