TM-9-2320-260-34-1 - Page 272 of 657

TM 9-2320-260-34-1

3-78. VALVE SEAT INSERTS MAINTENANCE (Contd)

b. Gaging and Counterboring

CAUTION

Before counterboring, each replacement valve seat insert outside

diameter and thickness must be measured and compared to

relating valve seat insert counterbore in the cylinder head. These

measurements will prevent overboring and damage to the cylinder

head.

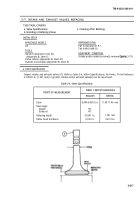

1. Measure valve seat insert (1) outside diameter and thickness. Refer to table 3-5, Valve Seat Insert

Specifications, for measurements. Replace valve seat insert (1) if valve seat insert (1) does not meet

specifications.

2. Measure insert counterbore (2) depth and inside diameter. Refer to table 3-5, Valve Seat Insert

Specifications, for measurements. Perform counterboring procedures if insert counterbore (2) does

not meet specifications.

Table 3-5. Valve Seat Insert Specifkations.

VALVE SEAT INSERT

VALVE SEAT INSERT

INSERT COUNTERBORE

INSERT COUNTERBORE

THICKNESS

OUTSIDE DIAMETER

DEPTH

INSIDE DIAMETER

0.278-0.282

in.

2.0025-2.0035

in.

Standard

1.9995-2.0005 in.

(7.0612-7.1628 mm)

(50.864-50.889

mm)

(50.787-50.813 mm)

NOTE

When using counterbore cutter, center the cutter in the insert

counterbore and valve guide arbor.

Allow counterbore cutter to turn several revolutions at exact

3.

moment the proper depth in cylinder head is reached to ensure

a perfectly flat bottom of bore for valve seats to seat.

Using counterbore cutter and valve guide arbor, cut insert counterbore (2) 0.006-0.010 in.

(0.152-0.254 mm) deeper than valve seat insert (1) thickness. This will allow staking of cylinder

head (3) to secure valve seat insert (1).

3-220

Back to Top