TM-9-2320-260-34-1 - Page 280 of 657

TM 9-2320-260-34-1

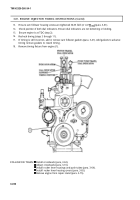

3-80. VALVE SEAT GRINDING

THIS TASK COVERS:

a. Dressing Grinding Wheel

d. Cleaning

b. Pre-Grinding Operation

e. Gaging Valve Seats

c. Valve Seat Grinding

f. Lapping Valve Seats

INITIAL SETUP

APPLICABLE MODELS

REFERENCES (TM)

All

TM 9-2320 -260-34P-1

TOOLS

EQUIPMENT CONDITION

General mechanic’s tool kit

New valve seat insert(s) installed (para. 3-78).

(Appendix B, Item 1)

Dial indicator (Appendix B, Item 11)

GENERAL SAFETY INSTRUCTIONS

Valve guide arbor (Appendix B, Item 44)

l Keep fire extinguisher nearby when using

Valve grinder (Appendix B, Item 62)

drycleaning solvent.

Wire brush (Appendix B, Item 71)

l Compressed air source will not exceed 30 psi

MATERIALS/PARTS

(207 kPa).

l Eyeshields must be worn when cleaning with

Lubricating oil (Appendix C, Item 20)

compressed air.

Drycleaning solvent (Appendix C, Item 48)

l Eyeshields must be worn during grinding

Lint-free cloth (Appendix C, Item 9)

operations.

Prussian blue (Appendix C, Item 26)

Coarse lapping and grinding compound

(Appendix C, Item 18)

Medium lapping and grinding compound

(Appendix C, Item 19)

WARNING

Eyeshields must be worn during grinding operations. Failure to

wear eyeshields may result in injury to personnel.

a. Dressing Grinding Wheel

CAUTION

Intake and exhaust valve seating surface to cylinder head valve

seat is critical. Accurate machining is required to provide for

perfect sealing of combustion chambers.

1. Position grinder driver and grinder wheel stone on tool holder stand with grinder wheel stone facing

down.

2. Position tool holder at 30° and lock screw.

3. Position electric grinder motor above angle quadrant, position chuck on grinder driver, and turn

grinder motor switch to “ON” position.

4. Slowly move control handle and draw tool bit across face of grinder wheel stone for test cut.

3-228

Back to Top