TM-9-2320-260-34-1 - Page 294 of 657

TM 9-2320-260-34-1

3-82. INJECTOR AND VALVE ADJUSTMENT (DIAL INDICATOR METHOD) (Contd)

13.

14.

15.

16.

17.

18.

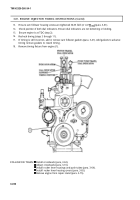

Loosen locknut (1) on intake rocker lever (3) of cylinder No. 5 and back out adjusting screw (2).

NOTE

Clearance for cold-set intake valves is 0.011 in. (0.28 mm).

Clearance for cold-set exhaust valves is 0.027 in. (0.69 mm).

Using feeler gage, measure clearance between intake rocker lever (3) nose and crosshead (4).

Slowly turn adjusting screw (2) until intake rocker lever (3) nose touches feeler gage. There will be

a slight drag on feeler gage when clearance is correct.

NOTE

Ensure adjusting screw does not move when tightening locknut.

When clearance is correct, hold adjusting screw (2) in place with screwdriver and tighen locknut (1)

40-45 lb-ft (54-61 N.m).

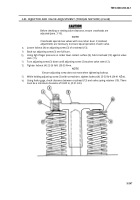

Perform adjustment procedures (steps 13 through 16) on exhaust rocker lever.

NOTE

After each set of injector and valve adjustments, advance pulley

to next timing mark and adjust injector and valve until all

timing is complete.

Two complete revolutions of the pulley are required to adjust all

injectors and valves.

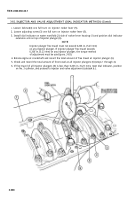

Advance accessory drive pulley (6) until the next timing mark (7) (table 3-6, Injector and Valve Set

Position) is alined with the pointer (8) on gearcase (5) and perform injector and valve adjustments

(steps 1 through 17) indicated in table 3-6, Injector and Valve Set Position.

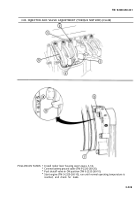

Table 3-6. Injector and Valve Set Position.

ADJUST

ROTATION

PULLEY

CYLINDER

DIRECTION

POSITION

INJECTOR

I

VALVE

Start

Advance to

Advance to

Advance to

Advance to

Advance to

1-6 "VS"

2-5 "VS"

3-4 "VS"

1-6 "VS"

2-5 "VS"

3-4 "VS"

3

6

2

4

1

5

5

3

6

2

4

1

3-242

Back to Top