TM-9-2320-260-34-1 - Page 296 of 657

TM 9-2320-260-34-1

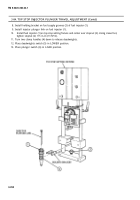

3-83. INJECTOR AND VALVE ADJUSTMENT (TORQUE METHOD)

THIS TASK COVERS:

a. Pre-Adjustment Setup

b. Injector and Valve Adjustment

INITIAL SETUP

APPLICABI.E MODELS

All

TOOLS

General mechanic’s tool kit

(Appendix B, Item 1)

Feeler gage (Appendix B, Item 58)

Torque wrench, 3/8-in. dr.

(Appendix B, Item 4)

Torque wrench, 1/2-in. dr.

(Appendix B, Item 3)

REFERENCES (TM)

TM 9-2320-260-10

EQUIPMENT CONDITION

Fuel shutoff valve in OFF position

(TM 9-2320-260-10).

Battery ground cable disconnected

(TM 9-2320-260-20).

Rocker lever housing covers removed (para. 3-14).

Valve crossheads adjusted (para. 3-16).

GENERAL SAFETY INSTRUCTIONS

If task is being performed while engine is in vehicle,

ensure fuel shutoff valve is in OFF position and

battery ground cable is disconnected to prevent

engine from starting.

TM 9-2320-260-20

TM 9-2320-260-34P-1

WARNING

If adjustment is being performed while engine is in vehicle, ensure

fuel shutoff valve is in OFF position and battery ground cable is

disconnected to prevent engine from starting. Failure to do so may

result in injury to personnel.

a. Pre-Adjustment Setup

CAUTION

This procedure is for non-top stop injectors. It is used to prevent

excessive loading of the injector actuating system and possible

failure.

NOTE

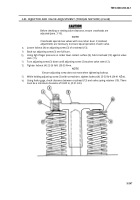

Injector plungers are adjusted before valves are adjusted.

Loosening all injector rocker lever adjusting screws and locknuts

will help indicate which cylinders have been adjusted and those

cylinders that still need to be adjusted.

All injectors and valves are adjusted the same. This procedure

covers the injection and valve adjustment for one cylinder head.

1.

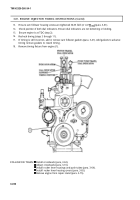

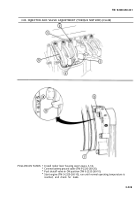

Loosen six locknuts (3) one full turn on six injector rocker levers (1).

2.

Loosen six adjusting screws (2) one full turn on six injector rocker levers (1).

3.

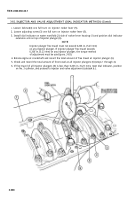

Turn accessory drive pulley (5) on gearcase (4) in direction of operating rotation until timing

mark (6), 1-6 “VS”, aline with pointer (7) on gearcase cover (4).

3-244

Back to Top