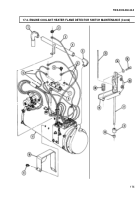

TM-9-2320-260-34-2 - Page 705 of 863

17-3. ENGINE COOLANT HEATER FLAME DETECTOR SWITCH MAINTENANCE

THIS TASK COVERS:

a. Removal

d. Assembly

b. Disassembly

e. Installation

c. Inspection

INITIAL SETUP

APPLICABLE MODELS

All

TEST EQUIPMENT

Multimeter (Appendix B, Item 115)

TOOLS

General mechanic’s tool kit

(Appendix B, Item 1)

Tool kit, electrical (Appendix B, Item 106)

MATERIALS/PARTS

Five screw-assembled lockwashers

(Appendix D, Item 384)

MATERIALS/PARTS (Contd)

Four screw-assembled Iockwashers

(Appendix D, Item 386)

Sleeve (Appendix D, Item 509)

Insulation varnish (Appendix C, Item 17)

REFERENCES (TM)

TM 9-2320-260-20

TM 9-2320-260-34P-2

EQUIPMENT CONDITION

Engine coolant heater removed (TM 9-2320-260-20).

NOTE

Tag wires for installation.

a .Removal

1. Remove four screw-assembled lockwashers (9) and guard (10) from heater housing (11). Discard

screw-assembled lockwashers (9).

2. Remove nut-assembled lockwasher (2), ground lead (3), air tube (4), and elbows (1) and (5) from

heater housing (11).

3. Remove five screw-assembled lockwashers (12) and six leads (6) from flame detector switch (7).

Discard screw-assembled lockwashers (12).

4. Loosen nut (8) and remove flame detector switch (7) from heater housing (11).

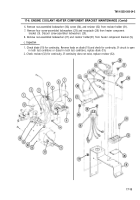

b. Disassembly

1. Remove adjusting screw (15), washer (14), and spring (20) from microswitch (16) and mount (19).

CAUTION

Ceramic rod is very brittle and is easily broken; handle carefully.

2. Tilt microswitch (16) back on mount (19), invert, and remove ceramic rod (13) from probe (17).

3. Remove sleeve (18) and nut (8) from probe (17). Discard sleeve (18).

c. Inspection

1. Inspect probe (17) of flange detector switch (7) for bends and corrosion. Remove corrosion from

probe (17). Replace flame detector switch (7) if bent.

2. Inspect ceramic rod (13) for chips, cracks, and breaks. Replace ceramic rod (13) if chipped, cracked,

or broken.

17-4

TM 9-2320-260-34-2

Back to Top