TM-9-2320-272-23-1 - Page 228 of 1313

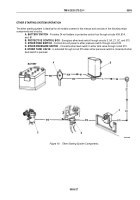

POWERTRAIN SYSTEM OPERATION

The powertrain system is the same on all models in this manual except the extra-long wheelbase models, which

have an additional propeller shaft and center bearing. This system transmits engine power to the axles to put the

vehicle in motion. Major components of the powertrain system are:

A. UNIVERSAL JOINTS

- Connections between two propeller shafts that permit one to drive the other even

though they may be at different angles.

B. DIFFERENTIALS

- Distribute power to left and right axle shafts.

C. AXLES

- Transmit power from differentials to rotate wheels.

D. PROPELLER SHAFTS

- Serve as driving shafts that connect transmission to transfer case and transfer

case to differentials.

E. ENGINE

- Provides power needed for powertrain component operation.

F. TRANSMISSION

- Adapts engine power to meet different driving conditions.

G. CENTER BEARING

- Provides support for propeller shaft to decrease vibration and wear on universal

joints (M927/A1/A2, M928/A1/A2, and M934/A1/A2 series only).

H. TRANSFER CASE

- Distributes power evenly to front and rear axles.

C

D

E

F

G

H

A

B

G0028DAA

Figure 16.

Powertrain System Components.

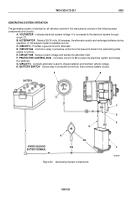

ELECTRICAL SYSTEM OPERATION

Nearly every component of models covered in this manual is affected by the electrical system. These components

and their electrical connections are described as part of the following electrical subsystems:

1.

Battery System Operation.

2.

Starting System Operation.

3.

Ether Starting System Operation.

4.

Generating System Operation.

5.

Directional Signal System Operation.

6.

Heating System Operation.

7.

Indicator, Gauge, and Warning System Operation.

8.

Trailer and Semitrailer Connection System Operation.

TM 9-2320-272-23-1

0003

0003-23

Back to Top