TM-9-2320-272-23-3 - Page 1115 of 1469

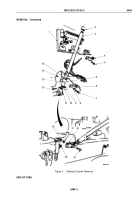

DISASSEMBLY

1.

Bend tabs (Figure 2, Item 2) and slide retainer (Figure 2, Item 1) and felt seal (Figure 2, Item 3) back on lower

section (Figure 2, Item 7).

2.

Remove lower steering column lower section (Figure 2, Item 7) from lower steering column upper section

(Figure 2, Item 4).

3.

Remove felt seal (Figure 2, Item 3) and retainer (Figure 2, Item 1) from lower steering column lower section

(Figure 2, Item 7). Discard retainer and felt seal.

4.

Remove grease fitting (Figure 2, Item 6) from lower steering column upper section (Figure 2, Item 7).

5.

Remove two grease fittings (Figure 2, Item 6) from universal joints (Figure 2, Item 5).

NOTE

Procedures to dissemble both universal joints are the same. Steps (6) through (8) are for the

lower universal joint.

6.

Remove four snaprings (Figure 2, Item 9) from universal joint bearing caps (Figure 2, Items 10 and 12).

7.

Remove two universal joint bearing caps (Figure 2, Item 10) and universal joint (Figure 2, Item 11) from lower

steering column end (Figure 2, Item 8).

8.

Remove two universal joint bearing caps (Figure 2, Item 12) and universal joint (Figure 2, Item 11) from lower

steering column lower section (Figure 2, Item 7).

END OF TASK

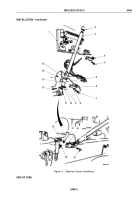

CLEANING, INSPECTION, AND REPAIR

WARNING

•

Solvent cleaning compound is flammable and toxic. Do not use near an open flame and

always have a fire extinguisher nearby when solvents are used. Use only in well-

ventilated places, wear protective clothing, and dispose of cleaning rags in approved

container. Failure to comply may result in damage to equipment, injury, or death to

personnel.

•

Compressed air source will not exceed 30 psi (207 kPa). When cleaning with compressed

air, eyeshields must be worn. Failure to comply may result in injury or death to personnel.

1.

Clean all steering column components with solvent cleaning compound and dry with compressed air.

2.

Inspect for cracks and burrs on splines. Repair small nicks or burrs. Replace lower section (Figure 2, Item 7)

and upper section (Figure 2, Item 4) if cracked or minor repairs cannot be made.

3.

Inspect bearing caps (Figure 2, Item 12) for damage. Replace bearing caps if damaged.

4.

Inspect universal joint (Figure 2, Item 11) for rough or uneven bearing surfaces. Replace universal joint if

surfaces are rough or uneven.

TM 9-2320-272-23-3

0494

0494-4

Back to Top