TM-9-2320-272-23-4 - Page 925 of 1393

CLEANING AND INSPECTION

WARNING

Solvent cleaning compound is flammable and toxic. Do not use near an open flame and

always have a fire extinguisher nearby when solvents are used. Use only in well-ventilated

places, wear protective clothing, and dispose of cleaning rags in approved container. Failure

to comply may result in damage to equipment, injury, or death to personnel.

1.

Clean all control valve components with solvent cleaning compound and dry with lint-free cloth (Volume 5,

WP

0817).

2.

Inspect spool valve and crane control valve. Replace crane control valve if grooved, scratched, cracked,

or

broken.

END OF TASK

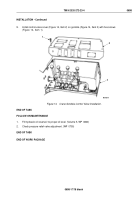

ASSEMBLY

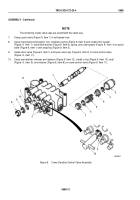

NOTE

Drain sleeve should go into control valve far enough to leave to or three full threads exposed.

Installing seat retainer plug at this point sets the seat retainer to the proper depth.

1.

Install seat retainer (Figure 8, Item 12) and drain sleeve (Figure 8, Item 13) in crane control valve

(Figure

8,

Item

1).

2.

Install seat retainer plug (Figure 8, Item 11) in crane control valve (Figure 8, Item 1).

3.

Install poppet assembly (Figure 8, Item 16) and poppet spring (Figure 8, Item 15) in crane control valve

(Figure

8,

Item

1) so poppet assembly points toward seat retainer (Figure 8, Item 12).

4.

Install relief valve (Figure 8, Item 14) on crane control valve (Figure 8, Item 1).

5.

Install o-rings (Figure 8, Items 4 and 5), backup rings (Figure 8, Items 2 and 3), o-ring (Figure

8,

Item

7), and

backup ring (Figure 8, Item 8) on each check valve cap (Figure 8, Item 6).

6.

Install two poppets (Figure 8, Item 10), springs (Figure 8, Item 9), and check valve caps (Figure 8, Item 6) into

crane control valve (Figure 8, Item 1).

TM 9-2320-272-23-4

0698

0698-10

Back to Top