TM-9-2320-272-24-1 - Page 398 of 1015

3-8. OIL

TM 9-2320-272-24-1

THIS TASK COVERS:

a. Removal

b. Inspection

c. Installation

INITIAL SETUP:

APPLICABLE MODELS

M939/A1

TOOLS

REFERENCES (TM)

LO 9-2320-272-12

TM 9-2320-272-10

TM 9-2320-272-24P

General mechanic’s tool kit (Appendix E, Item 1)

Torque wrench (Appendix E, Item 146)

EQUIPMENT CONDITION

MATERIALS/PARTS

Parking brake set (TM 9-2320-272-10).

Hood raised and secured (TM 9-2320-272-10).

Antiseize tape (Appendix C, Item 72)

Left splash shield removed (TM 9-2320-272-10).

Engine oil drained (para. 3-5).

NOTE

Have adequate drainage container ready to catch oil.

1.

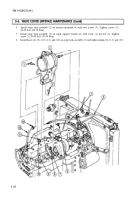

Remove two screws (7), washers (8), and clamps (6) from oil pump pickup and return hoses (2)

and (3) and engine oil pan (5).

2.

Disconnect oil pump return hose (3) from adapter (9) and oil pan aerator (4).

3.

Remove adapter (9), elbow (10), and nipple (11) from oil pump (1).

1.

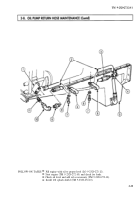

Inspect oil pump return hose (3). Replace hose (3) if cracked, frayed, or split.

2.

Inspect adapter (9), elbow (10), and nipple (11). Replace if adapter (9), elbow (10), or nipple (11)

have cracks or threads are stripped or crossed.

1.

Apply antiseize tape to male pipe threads of oil pump return hose (3), adapter (9), and nipple (11).

2.

Install nipple (11), elbow (10), and adapter (9) on oil pump (1).

3.

Connect oil pump return hose (3) to oil pan aerator (4) and adapter (91.

4.

Install two clamps (6) and oil pump pickup and return hoses (2) and (3) on engine oil pan (5) with

two washers (8) and screws (7). Tighten screws (7) 35-40 lb-ft (47-54 N•m).

3-34

Back to Top