TM-9-2320-272-24-1 - Page 400 of 1015

3-9. FRONT

TM 9-2320-272-24-1

THIS TASK COVERS:

a. Removal

b. Inspection

c. Installation

INITIAL SETUP:

APPLICABLE MODELS

REFERENCES (TM)

M939/A1

TM 9-2320-272-10

TOOLS

TM 9-2320-272-24P

General mechanic’s tool kit (Appendix E, Item 1)

EQUIPMENT CONDITION

MATERIALS/PARTS

Parking brake set (TM 9-2320-272-10).

Hood raised and secured (TM 9-2320-272-10).

Two bushings (Appendix D, Item 23)

Antiseize tape (Appendix C. Item 72)

Left splash shield removed (TM 9-2320-272-10).

NOTE

Have adequate drainage container ready to catch oil.

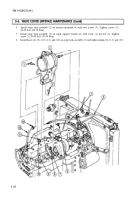

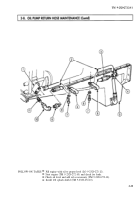

1.

Loosen two nuts (4) on sump tube (5), and slide nuts (4) toward center of front sump tube (5).

2.

Tighten elbow (3) 1/4 turn to free sump tube (5). Remove sump tube (5) from adapter (6) and

elbow (3).

3.

Remove two bushings (7) from sump tube (5). Discard bushings (7).

NOTE

Mark position of elbow for installation.

4.

Remove adapter (6) from oil pan (2), and elbow (3) from oil pump (1).

1.

Inspect two nuts (4), elbow (3), and adapter (6). Replace nuts (4), elbow (3), or adapter (6) if threads

are damaged.

2.

Inspect sump tube (5). Replace if cracked.

1.

Apply antiseize tape to male pipe threads of adapter (6) and elbow (3).

NOTE

Ensure elbow is less than 1/8 turn from final position to allow

room for installation of front sump tube.

2.

Install adapter (6) on oil pan (2), and elbow (3) on oil pump (1).

3.

Install two nuts (4) and new bushings (7) on sump tube (5), and slide toward center of sump tube (5).

4.

Position one end of sump tube (5) on adapter (6), and start elbow (3) in other end of sump tube (5).

Turn elbow (3) to tighten into final position, pressing front sump tube (5) into elbow (3) and aligning

front sump tube (5) with elbow (3).

5.

Connect sump tube (5) to adapter (6) and elbow (3) by tightening two nuts (4).

3-36

Back to Top