TM-9-2320-272-24-3 - Page 310 of 799

TM 9-2320-272-24-3

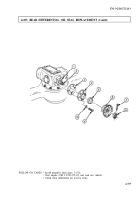

4-102. FRONT DIFFERENTIAL 0IL SEAL REPLACEMENT

THIS TASK COVERS:

a. Removal

b. Installation

INITIAL SETUP:

APPLICABLE MODELS

All

TOOLS

General mechanic’s tool kit (Appendix E, Item 1)

Torque wrench (Appendix E, Item 145)

Mechanical puller (Appendix E, Item 102)

MATERIALS/PARTS

Gasket (Appendix D, Item 206)

Oil seal (Appendix D, Item 500)

Cotter pin (Appendix D, Item 61)

Gasket (Appendix D, Item 207)

GAA grease (Appendix C, Item 28)

Sealing compound (Appendix C, Item 30)

REFERENCES (TM)

TM 9-2320-272-10

TM 9-2320-272-24P

EQUIPMENT CONDITION

• Parking brake set (TM 9-2320-272-10).

• Rear wheels chocked (TM 9-2320-272-10).

• Propeller shaft removed (para. 3-149).

1.

Remove cotter pin (1) and nut (11) from driveshaft (8). Discard cotter pin (1).

2.

Using mechanical puller, remove companion flange (2) from driveshaft (8).

CAUTION

Do not jam any tool between differential and pinion shaft retainer

when removing front bearing cover. Shims will be damaged.

3.

Remove eight screws (10), washers (9), front bearing cover (3), and gasket (6) from differential

carrier (7). Discard gasket (6).

4.

Remove oil seal (5) and gasket (4) from front bearing cover (3). Discard oil seal (5) and gasket (4).

b. Installation

1.

Position new gasket (4) in front bearing cover (3).

2.

Apply GAA grease to inside diameter of new oil seal (5). Apply sealing compound to outside

diameter of new oil seal (5).

3.

Install new oil seal (5) in front bearing cover (3).

4.

Apply sealing compound to mating surfaces of new gasket (6).

5.

Install new gasket (6) and front bearing cover (3) on differential carrier (7) with eight washers (9)

and screws (10). Tighten screws (10) 93-120 lb-ft (126-163 N•m).

6.

Install companion flange (2) on driveshaft (8) with nut (11). Tighten nut (11) 300-400 lb-ft

(407-542 N•m).

7.

Install new cotter pin (1) through nut (11) and driveshaft (8).

4-574

Back to Top