TM-9-2320-272-24-3 - Page 318 of 799

TM 9-2320-272-24-3

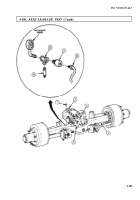

4-106. AXLE LEAKAGE TEST

THIS TASK COVERS:

a. Test

b. Corrective Action

INITIAL SETUP:

TOOLS

EQUIPMENT CONDITION

General mechanic’s tool kit (Appendix E, Item 1)

• Parking brake set (TM 9-2320-272-10)

Air pressure gauge

• Rear wheels chocked (TM 9-2320-272-10).

REFERENCES (TM)

TM 9-2320-272-10

TM 9-2320-272-24P

1.

Remove breather (1) from axle housing (4).

2.

Install nipple (9) and tee (6) on axle housing (4).

3.

Install air pressure gauge and quick-disconnect coupling (7) on tee (6).

CAUTION

Do not allow air pressure to exceed 15 psi (103 kPa). Seals will be

damaged if air pressure exceeds 15 psi (103 kPa).

4.

Connect air supply hose (8) to quick-disconnect coupling (7).

5.

Turn on air supply and observe air gauge. When air pressure reaches 8 psi (55 kPa), disconnect air

supply hose (8). Begin timing for a period of 45 seconds. After 45 seconds, check air gauge reading.

6.

If air gauge reading indicates leakage of 5 psi (35 kPa) or faster, perform corrective action

(task b.).

b. Corrective Action

1.

Tighten all axle housing (4) and differential carrier (5) nuts and screws.

2.

Reconnect air supply hose (8) to quick-disconnect coupling (7) and turn on air supply. When air

pressure reaches 8 psi (55 kPa), disconnect air supply hose (8).

3.

Apply soapsuds around front oil seal cover (2), rear oil seal cap (3), and base of differential

carrier (5) and axle housing (4). Air bubbles indicate defective or missing sealing compound. Remove

front oil seal cover (2), rear oil seal cap (3), or differential carrier (5) and reseal (para. 4-102, 4-103,

or 3-158).

4.

Remove quick-disconnect coupling (7), air pressure gauge, tee (6), and nipple (9) from axle housing (4).

5.

Install breather (1) on axle housing (4).

4-582

Back to Top