TM-9-2320-272-24-3 - Page 634 of 799

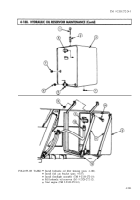

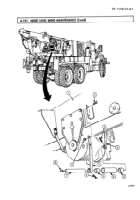

4-188. HYDRAULIC

TM 9-2320-272-24-3

THIS TASK COVERS:

a.

Removal

b.

Disassembly

c.

Cleaning, Inspection, and Repair

d. Assembly

e. Installation

INITIAL SETUP:

APPLICABLE MODELS

M936/A1/A2

TOOLS

General mechanic’s tool kit (Appendix E, Item 1)

MATERIALS/PARTS

Two locknuts (Appendix D, Item 291)

Three cap and plug sets (Appendix C, Item 14)

Antiseize tape (Appendix C, Item 72)

Drycleaning solvent (Appendix C, Item 71)

PERSONNEL REQUIRED

Two

REFERENCES (TM)

LO 9-2320-272-12

TM 9-2320-272-10

TM 9-2320-272-24P

EQUIPMENT CONDITION

•

Parking brake set (TM 9-2320-272-10).

• Floodlight assembly removed (TM 9-2320-272-102

• Fuel can bracket removed (para. 4-187).

• Hydraulic oil filter housing removed (para. 4-186).

• Hydraulic oil reservoir drained (para. 4-188).

CAUTION

When disconnecting hydraulic lines and hoses, plug all openings to

prevent dirt from entering and causing damage to parts.

NOTE

Have drainage container ready to catch oil.

1.

Disconnect hydraulic oil return hose (6) from adapter elbow (7).

2.

Remove two locknuts (1) and screws (2) from two oil reservoir retaining straps (4). Discard

locknuts (1) and separate straps (4) from hydraulic oil reservoir (3).

NOTE

Assistant will help with step 3.

3.

Remove hydraulic oil reservoir (3) from two oil reservoir brackets (5).

NOTE

If a new hydraulic oil reservoir is to be installed, perform step 4.

4.

Remove oil gauge (8), filter screen (9), two pipe plugs (10) and (13), adapter elbow (7), and

drainvalve (11) with pipe plug (12) from oil reservoir (3).

1.

Remove oil gauge (8) and filter screen (9) from top of oil reservoir (3).

2.

Remove adapter elbow (7), drainvalve (11), and pipe plugs (10) and (13) from oil reservoir (3).

3.

Remove pipe plug (12) from drainvalve (11).

4-898

Back to Top