TM-9-2320-272-24-3 - Page 646 of 799

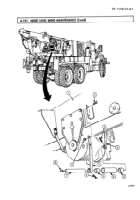

4-193. BOOM

TM 9-2320-272-24-3

THIS TASK COVERS:

a.

Removal

b.

Installation

INITIAL SETUP:

APPLICABLE MODEL

REFERENCES (TM]

M936/A1/A2

LO 9-2320-272-12

TOOLS

General mechanic’s tool kit (Appendix E, Item 1)

Torque wrench (Appendix E, Item 144)

Lifting device

Chain

TM 9-2320-272-10

TM 9-2320-272-24P

EQUIPMENT CONDITION

• Parking brake set (TM 9-2320-272-10).

• Boom lowered (TM 9-2320-272-10).

• Hydraulic oil reservoir drained (para 4-188).

MATERIALS/PARTS

Cotter pin (Appendix D, Item 59)

Lockwasher (Appendix D, Item 350)

Cap and plug set (Appendix D, Item 14)

PERSONNEL REQUIRED

Two

GENERAL SAFETY INSTRUCTIONS

• All personnel must stand clear during hoisting

operations.

• Elevating cylinder is heavy. Use caution when

removing or installing elevating cylinder.

CAUTION

When disconnecting hydraulic lines and hoses, plug all openings to

prevent dirt from entering and causing internal parts damage.

NOTE

Left and right elevating cylinders are removed and installed in the

same way. Bight elevating cylinder is covered in this procedure.

NOTE

• Have drainage container ready to catch oil.

• Tag lines for installation.

1.

Disconnect cylinder oil supply line (6) and oil return line (5) from cylinder adapter fitting (10) and

snubber valve (9) at bottom of elevating cylinder (11).

WARNING

All personnel must stand clear during hoisting operations. A

snapped cable, or shifting or swinging load, may cause injury to

personnel.

2.

Using chain and lifting device, lift boom (1) until boom (1) weight is fully supported and upper

retaining pin (2) is free.

3.

Remove screw (4), lockwasher (3), and upper retaining pin (2) from elevating cylinder (11) and

boom (1). Discard lockwasher (3).

WARNING

Elevating cylinder is heavy. Remove with the aid of assistant and

a lifting device or injury to personnel may result.

4.

Remove cotter pin (7), lower retaining pin (8), and elevating cylinder (11) from turntable (12).

Discard cotter pin (7).

4-910

Back to Top