TM-9-2320-272-24-3 - Page 648 of 799

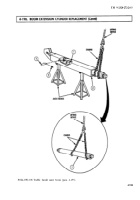

4-194. BOOM

TM 9-2320-272-24-3

THIS TASK COVERS:

a. Removal

b. Installation

INITIAL SETUP:

APPLICABLE MODELS

M936/A1/A2

TOOLS

General mechanic’s tool kit (Appendix E, Item 1)

Torque wrench (Appendix E, Item 145)

Lifting device

Chains

MATERIALS/PARTS

Locknut (Appendix D, Item 285)

Two lockwashers (Appendix D, Item 350)

Cap and plug set (Appendix C, Item 14)

1.

2.

3.

4.

5.

6.

7.

4-912

CAUTION

When disconnecting hydraulic lines and hoses, plug all openings to

prevent dirt from entering and causing internal damage to parts.

NOTE

• Have drainage container ready to catch oil.

• Tag hoses for installation.

Disconnect cylinder extension hose (5) and retracting hose (4) from two boom adapter elbows (3).

Secure inner boom (1) to outer boom (2) with utility chain to prevent inner boom (1) movement

during hoisting operation.

Attach two utility chains to outer boom (2).

Raise outer boom (2) until weight of boom (2) is fully supported and elevating cylinder retaining

pins (16) are free.

Remove two screws (14), lockwashers (15), and retaining pins (16) from outer boom (2) and two

elevating cylinders (13). Discard lockwashers (15).

WARNING

Before hoisting outer boom away from wrecker, ensure inner boom

is properly secured to outer boom as outlined in step 2 to prevent

injury to personnel.

Remove grease fittings (6) and (12) from pivot pin (7).

Remove locknut (11), pivot pin (7), two sleeve bearings (9), and crane sheave (10) from turntable (8).

Discard locknut (11).

REFERENCES (TM)

LO 9-2320-272-12

TM 9-2320-272-10

TM 9-2320-272-24P

EQUIPMENT CONDITION

• Parking brake set (TM 9-2320-272-10)

• Boom floodlight wire removed (para. 3-385).

• Hydraulic oil reservoir drained (para. 4-188).

• Hoist winch removed (para. 4-192).

GENERAL SAFETY INSTRUCTIONS

• All personnel must stand clear during hoisting

operations.

• Ensure inner boom is secured to outer boom before

hoisting.

WARNING

All personnel must stand clear during hoisting operations. A snapped

cable, or shifting or swinging load, may cause injury to personnel.

Back to Top