TM-9-2320-273-34 - Page 503 of 801

TM 9-2320-273-34

(2)

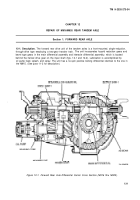

Insert a checking tool (made from a splined axle shaft end) into the differential nest (fig.

11-53). Allow the splines of the tool to engage with the spline of one

side gear only.

Figure 11-53. install the Checking Tool.

(3)

Using a suitable socket and torque wrench, rotate the differential nest while observing the

scale on the torque wrench (fig. 11-54). Correct rolling resistance of the differential assembly is 50 Ib-ft

(68 N·m) torque maximum applied to one side gear;

Figure 11-54 Check Rolling Resistance.

g. Install the Differential and Gear Assembly.

(1)

Pre-lubricate the differential bearings and cups with gear lube (item 30, A

PP

B).

(2)

place the cups over the bearings and position the assembly in the carrier housing,

(3)

Insert the bearing adjusting nuts and turn hand-tight against bearing cups.

11-57

Back to Top