TM-9-2320-273-34 - Page 493 of 801

TM 9-2320-273-34

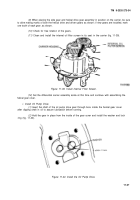

Use soft metal shields over vise jaws

to avoid damaging the cage.

b.

Secure the output shaft bearing cage in a vise and place the inner bearing cup in position in the

bearing cage and insert the output shaft with bearing cones through the cage.

c.

Position the outer bearing cup into the cage and over the bearing cone on the through shaft.

Secure bearings and shaft in the cage with a snap ring bearing spacer.

This snap ring also controls the

bearing end play.

NOTE

Do not assemble the oil seal or yoke

and spacer at this time.

11-12. Output Shaft Installation.

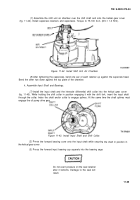

a. Adjust Bearing End Play.

NOTE

The output bearing end play is controlled by

the thickness of the snap ring bearing spacer.

The snap ring is available in thicknesses rang-

ing from 0.155-0.182 inch in increments of

0.003 inch. Select and install one snap ring

to obtain a 0.0001-0.0030 inch (0.0025-

0.0762 mm) bearing end play. Use the fol-

Iowing procedures.

(1)

With the bearing cage and through-shaft assembly secured in a vise, attach a dial indicator

to the cage flange. Adjust the indicator so its pointer contacts the end of the through shaft and set the

dial to zero.

(2)

While observing the dial, pull the through-shaft to rack in the output bearings while

turning the shaft side-to-side to seat the bearings.

(3)

Next, push the through-shaft while turning it side-to-side and take note of the dial

indicator reading.

(4)

Final end play should be between 0.0001-0.0030 inch. If the bearing end play does not

fall within this range, replace the snap ring bearing spacer.

NOTE

A thinner snap ring will increase end play,

and a thicker snap ring will decrease end

play.

(5)

After establishing correct bearing end play, assemble the yoke spacer and yoke onto the

through-shaft against the outer bearing. Secure the yoke with nut and torque to 450-600 Ib-ft

(610-813 N•m).

11-47

CAUTION

Back to Top