TM-9-2320-273-34 - Page 734 of 801

TM 9-2320-273-34

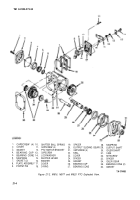

21-5. Disassembly of PTO (M918).

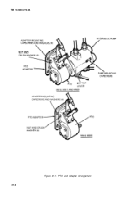

a.

Remove six nuts and crush washers that fasten the PTO to the adapter (fig. 21-1). Separate the

PTO and the adapter. Remove gasket (38, fig. 21-3) from case (30).

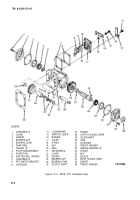

b.

Remove three capscrews (11) from cover (17). (The fourth capscrew (11) was removed during

the PTO cable removal procedure). Remove PTO switch bracket (12).

c. Remove capscrew (13) and Iockwasher (14) that fastens the shifter lever (15) to the cover. Mark

the lever and the spindle so that they can go back together in the same position. Pull off the lever (15),

washer (16) and cover (17). Remove O-ring (18). Remove plate subassembly (8).

d.

1 Remove poppet pin (9) and shifter ball spring (10), if required.

e.

Remove two gaskets (7).

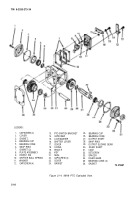

f.

Back out setscrew (31) flush to surface of case (30).

g.

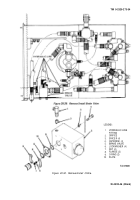

Press out idler shaft (29). Remove two thrustwashers (32) and (39) and input sliding gear (37)

with sleeve (36), needle bearings (33) and spacer (34) still inside. Carefully remove spacer and needle

bearings (17 per set, 34 total) and keep in sets if possible.

h.

Press sleeve (36) out of input sliding gear (37) and remove key (35).

.

Remove four capscrews (1) and carefully pry off cover (2) with attached bearing cup (4).

Remove gasket (3) and press out bearing cup, if required.

i.

Remove key (19) from end of output shaft (26). Remove four capscrews (21) and carefully

pry off cover (22) with seal (20) and bearing

CUP

(24) attached. Remove gasket (23). If required, pry

out seal and press out bearing cup.

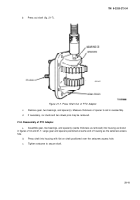

k.

Using a suitable bearing puller, remove bearing cone (5) from end of output shaft (26). (See

fig. 21-5).

/. Remove snapring (6) and pull output shaft (26) out from opposite end of case (30). Remove

spacer (27).

m

Remove bearing cone (25) with a suitable puller.

n.

Pull output sliding gear (28) out of case (30).

21-5

Back to Top