TM-9-2320-279-20-1 - Page 356 of 985

TM 9-2320-279-20-1

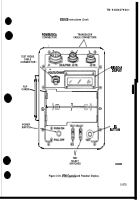

STE/lCE

Instructions (Cent)

2-16.

SIMPLIFIED TEST EQUIPMENT FOR INTERNAL COMBUSTION ENGINES (STE/lCE)

@

INTRODUCTION (CONT).

(2)

TEST SELECT SWITCHES.

The TEST SELECT switches are used to select the actual test to be

~erformed. There are ten ~ositions on each switch numbered O through 9. The number dialed into these

●

.

switches is read by the ‘; ’TM when you press the TEST button. Chang;ng the TEST SELECT switch position

has no effect until the TEST button is pushed.

(3)

TEST B~lTTO”

Depressing and releasing the TEST button causes the test measurement to begin.

The measured value will appear on the readout display. The reading will be in units normally used for the

particular vehicle measurement. These units are listed on the flip cards. The TEST BU’lX)N must be

pressed and immediately released. Depressing and holding the TEST BUTlON down initiates an offset test

as described in k.(3).

(4)

READOUT DISPJQW

The READOUT DISPLAY will show different types of readouts during

testing up to a maximum of 4 characters (for example .8.8.8.8). The types of readouts are described in

detail later in this paragraph but are summarized as follows:

(a) Status Readout.

This type of readout keeps the operator informed of what is happening such as

power applied, failed test, etc.

(b)

Numerical Readout.

This type of readout is the measured value in units of the measurement

being made. For example, if measuring O-45 volts DC, the number 24 on the display indicates 24-volts.

(c)

Error Readout.

This type of readout indicates that, for example, the wrong test number was

selected, the transducer is not connected, or the VTM is faulty.

(5)

FLIP CARDS.

The flip cards list the 2-digit test number system for selecting the various tests.

The cards also summarize the test operating instructions contained in this chapter.

(6)

POWER/DCA CONNECTOR J1.

Connector J1 connects the VTM to either a vehicle diagnostic

connector using the DCA cable, or to the vehicle batteries using the power cable. Operating power and

signals from the transducers are supplied to the VTM through the DCA cable.

(7)

TRANSDUCER CABLE CONNECTORS J2 and J3.

Connector J2 or J3 connects the VTM to any

transducer in the transducer kit. Operating power is supplied to the transducer and signals from the

transducer are supplied to the VTM through the cable. Connectors J2 and J3 are identical and can be

interchanged with each other or used in combination.

(8)

TEST PROBE CABLE CONNECTOR J-4.

Connector J4 connects test leads to the VTM when doing

manual voltage and resistance tests.

g. Cc#b/e Assemblies.

Cable assemblies are shown in Figure 2-21. Cable assemblies are referred to by

cable number and by a name which describes how the cable is used. For example, cable W 1 is the DCA

cable, cable W2 is the Test Probe cable, etc. If necessary, the two transducer cables (W4) can be joined with

the adapter supplied in the transducer kit to make one long cable. When cables are connected, the large

key on the cable connector mates with a keyway on the transducer connector or the VTM connector for

proper installation. Figure 2-22 shows how the key and keyway should be lined up. If there is any

difficulty during testing, and it is suspected that a cable is bad, refer to TM 9-4910-571-12&P to check cable

continuity.

h.

Transducer

Kit (TK).

The Transducer Kit (TK) is shown in Figure 2-23. The kit contains

transducers, adapters, and fittings stored in a molded tray. Many of the fittings do not have part number

markings. However, the number shown with each item will help to identify the item easily. Before

installing any Transducer Kit items on the vehicle, be sure to clean the mounting surfaces. This is

particularly important if opening fuel lines or tapping into manifolds. Dirt particles entering the engine can

cause damage to both the engine and the transducer kit items. The transducers are precise devices housed

in rugged bodies. However, they should be kept clean and handled with reasonable care. In particular, keep

the connectors free of dirt and grease.

2-276

Back to Top