TM-9-2320-280-34 - Page 289 of 1258

TM 9-2320-280-34

6-3.

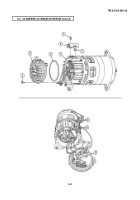

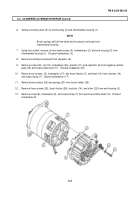

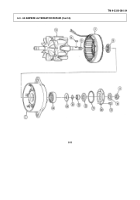

60 AMPERE ALTERNATOR REPAIR

This task covers:

a.

Removal

d.

Assembly

b.

Cleaning

e.

Bench Testing

c.

Inspection

INITIAL SETUP:

Tools

Materials/Parts (Cont'd)

General mechanic's tool kit:

Grease (Appendix B, Item 20)

automotive (Appendix G, Item 1)

Insulating compound (Appendix B, Item 26)

Lubricating oil (Appendix B, Item 33)

Test Equipment

Silicone compound (Appendix B, Item 56)

Multimeter (Appendix G, Item 120)

Seal sleeve tool (Appendix C, Fig.

6)

Special Tools

Manual References

Torx socket (Appendix G, Item 28)

TM 9-214

TM 9-2320-280-20

Materials/Parts

TM 9-2320-280-24P

Locknut and woodruff key kit

(Appendix E, Item 67)

Personnel Required

Slip ring end kit (Appendix E, Item 202)

One mechanic

Drive end kit (Appendix E, Item 12)

One assistant

Fifteen lockwashers (Appendix E, Item 83)

Two screw and lockwasher assemblies

Equipment Condition

(Appendix E, Item 147)

•

Alternator removed (TM 9-2320-280-20).

Strap (Appendix E, Item 206)

•

Alternator pulley removed (TM 9-2320-280-20).

Adhesive sealant (Appendix B, Item 2)

Maintenance Level

Direct support

a.

Disassembly

NOTE

Prior to removal, tag leads for installation.

1.

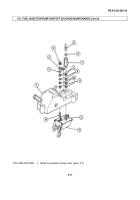

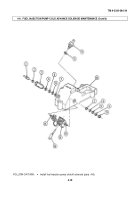

Remove access plug (7) from end housing (4).

2.

Remove six screws (1), end cover (2), and O-ring (3) from end housing (4).

Disconnect four leads (10)

from four terminals (11) on regulator (12).

Discard O-ring (3).

NOTE

Regulator is part of end cover.

Do not disassemble.

3.

Remove two screw and lockwasher assemblies (6) and output plate cover (5) from end housing (4).

Discard screw and lockwasher assemblies (6).

4.

Remove sealer from three stator leads (8).

5.

Unsolder and disconnect three stator leads (8) from three stator lead terminals (9).

6-2

Back to Top