TM-9-2320-280-34 - Page 297 of 1258

TM 9-2320-280-34

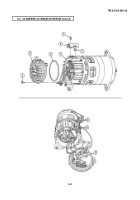

6-3.

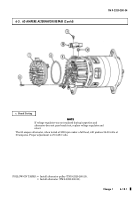

60 AMPERE ALTERNATOR REPAIR (Cont ’d)

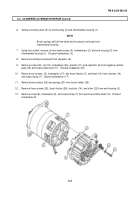

b.

Cleaning

Clean all alternator components in accordance with para.

2-13.

c.

Inspection

NOTE

For general inspection instructions, refer to para.

2-14.

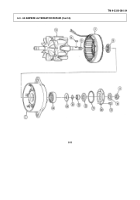

1.

Inspect end housing (2) for cracks, breaks, and stripped threads.

Replace end housing (2) if defective.

2.

Check the brushes (11) for roughness, galling, and wear.

Replace brushes (11) if defective.

Replace

brushes (11) if brush length is less than 0.25 in.

(6.35 mm).

3.

Check the brush springs (10) for damage.

Replace brush springs (10) if damaged.

4.

Check the output plate (1) for burned, frayed, or broken wiring.

Replace output plate (1) if defective.

5.

Check rectifier terminals (4) and (6) for continuity in one direction and infinite resistance in opposite

direction.

Check for shorts from rectifier terminals (4) and (6) to rectifier plates (5) and (7).

Replace

rectifier plates (5) and (7) if defective.

6.

Check the rotor (12) and stator (13) for shorts, grounds, and open circuits.

Inspect rotor (12)

bearings surfaces (refer to TM 9-214).

Replace alternator if defective.

7.

Check brush holder (8), brush holder insulator (9), and positive rectifier insulator (3) for cracks and

breaks.

Replace brush holder (8), brush holder insulator (9), or positive rectifier insulator (3) if

defective.

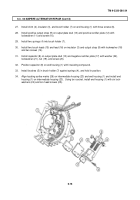

8.

Inspect intermediate housing (15) for cracks, breaks, and stripped threads.

Replace alternator if

defective.

9.

Inspect drive end housing (14) for cracks and breaks.

Replace drive end housing (14) if defective.

10.

If all components pass testing, replace regulator (16).

6-10

Back to Top