TM-9-2320-361-20 - Page 525 of 1207

TM 9-2320-361-20

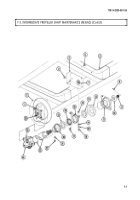

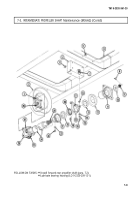

7-3. INTERMEDIATE PROPELLER SHAFT MAINTENANCE (M36A2)

This task covers:

a. Removal

d. Assembly

b. Disassembly

e. Installation

c. Cleaning and Inspection

INITIAL SETUP:

APPLICABLE MODELS

REFERENCES (TM)

M36A2

LO 9-2320-209-12-1

MATERIALS/PARTS

TM 9-214

TM 9-2320-361-20P

Two seals

Ten locknuts

EQUIPMENT CONDITION

Cotter pin

Forward-rear axle propeller shaft removed

Lockwasher

(para. 7-2).

GAA grease (Appendix C, Item 13)

Drycleaning solvent (Appendix C, Item 26)

GENERAL SAFETY INSTRUCTIONS

Rags (Appendix C, Item 21)

Keep fire extinguisher nearby when using

drycleaning solvent.

PERSONNEL REQUIRED

Two

1.

2.

3.

4.

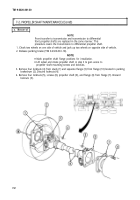

Remove cotter pin (8), nut (9), washer (10), flange (11), and deflector (12) from shaft (23). Discard

cotter pin (8).

NOTE

Assistant will help with step 2.

Remove two locknuts (16), washers (15), screws (7), propeller shaft (23), and bearing housing (18)

from frame support (4). Discard locknuts (16).

NOTE

Mark yoke position for installation.

Remove four locknuts (25) and flange yoke (24) from flange (26) and studs (1) located in parking

brakedrum (2). Discard locknuts (25).

Remove four locknuts (3)

locknuts (3).

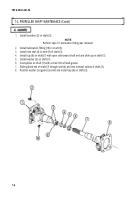

b. Disassembly

1. Remove bearing housing

screws (5), and frame support (4) from crossmember (6). Discard

18) from propeller shaft (23).

2. Remove screw (22), lockwasher (21), and side shield (20) from propeller shaft (23). Discard

lockwasher (21).

3. Remove two seals (13) and bearing (19) from bearing housing (18). Discard seals (13).

4. Remove four rubber insulators (14) from bearing housing (18).

NOTE

Perform step 5 if lubrication fitting is damaged.

5. Remove lubrication fitting (17) from bearing housing (18).

7-6

Back to Top