TM-9-2320-361-20 - Page 527 of 1207

TM 9-2320-361-20

a.

b.

c .

d.

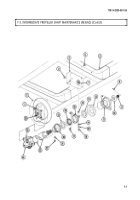

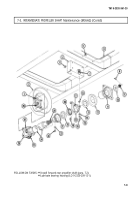

7-3. INTERMEDIATE PROPELLER SHAFT MAINTENANCE (M36A2) (Contd)

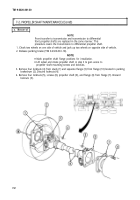

c. Cleaning and Inspection

WARNING

Drycleaning solvent is flammable and will not be used near open

flame. Use only in well-ventilated places. Failure to do so may

result in injury to personnel.

1. Clean and inspect bearing (20) in accordance with TM 9-214.

2. Inspect universal joint (25) for roughness and free play. Replace universal joint (25) if loose or rough

(para. 7-4).

3. Clean all parts with drycleaning solvent and dry with clean rag.

4. Inspect propeller shaft (24) for:

Breaks, cracks, or bends. Replace if cracked, bent, or broken.

Crossed or stripped threads. Replace if threads are crossed or stripped.

Nicked or burred splines (28). Replace if splines are cracked or chipped.

Bearing shoulder nicked, burred, or scored. Replace if bearing shoulder is nicked, burred,

scored, or bearing (20) is frozen.

5. Inspect shield (21) for cracks, breaks, or bends. Replace shield (21) if cracked, broken, or bent.

6. Inspect flange (11) for cracks, breaks, and bent deflector (12). Replace flange (11) if damaged.

7. Inspect rubber insulators (14) for tears or breaks. Replace rubber insulators (14) if torn or broken.

8. Inspect bearing housing (18) for cracks and breaks. Replace bearing housing (18) if cracked or

broken.

9. Inspect frame support (4) for breaks and cracks. Replace frame support (4) if broken or cracked.

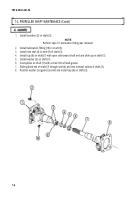

1. Apply a light film of GAA grease to bearing (20) outer race and inner bore (17) of bearing

housing (18). Install bearing (20) in bore (17). Ensure bearing (20) is seated square in bore (17) of

bearing housing (18).

2. Install two new seals (13) in shaft side of bearing housing (18).

3. Slide shield (21) on shaft (24) as far as it will go.

4. Install shield (21) with screw (23) and new lockwasher (22).

5. Install four rubber insulators (14) in bearing housing (18).

NOTE

Perform step 6 if lubrication fitting was removed.

6. Install lubrication fitting (19) in bearing housing (18).

1.

2.

3.

4.

5.

6.

7.

7-8

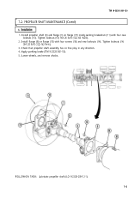

Install frame support (4) to crossmember (6) with four screws (5) and new locknuts (3).

Install flange yoke (26) on studs (1) of transfer flange (29) in parking brakedrum (2) with four new

locknuts (27). Ensure scribed marks aline. Tighten locknuts (27) 90-120 lb-ft (122-163 NŽm).

Install bearing housing (18) to frame support (4) with two screws (7), washers (15), and new

locknuts (16).

Install deflector (12) and flange (11) on shaft (24) with washer (10) and nut (9).

Tighten nut (9) on shaft (24) 260-290 lb-ft (353-393 NŽm).

Install new cotter pin (8) through nut (9).

Ensure shaft (24) turns freely and with no side play at U-joint (25) and support bearing (20).

Back to Top