TM-9-2320-361-20 - Page 666 of 1207

TM 9-2320-361-20

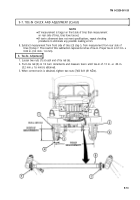

9-2. WHEEL, TIRE, AND TUBE MAINTENANCE (Contd)

e. Wheel Installation

1.

2.

3.

4.

5.

6.

CAUTION

When installing stud nuts, ensure to put the curved (ball seat)

surface of the nut toward the wheel to seat properly. Failure to do

this may result in damage to wheel.

NOTE

Wear of rear dual tires should be matched as closely as possible.

Valves on rear tires must be opposite each other (180° apart).

Ventilation holes in outer wheel should be directly alined with

ventilation holes in inner wheel.

Nuts have left-hand threads on left wheel assembly and right-

hand threads on right wheel assembly. Studs and nuts are

stamped (L) left and (R) right.

Assistant will help steps 1 and 3.

If inner-rear wheel is being replaced, ensure inner stud nuts are

properly seated when installed.

If inner-rear wheel is being installed, perform step 4. If outer-

rear wheel or front wheel is being installed, go to step 5.

Lift inner wheel (13) and install on wheel studs (12).

Install and hand tighten six new wheel capnuts (11) on wheel studs (12).

Lift wheel (10) and install on wheel capnuts (11) with six stud nuts (9). On front wheel, ensure

brake inspection plate (14) is visible through ventilation hole.

Tighten six wheel capnuts (11) 400-425 lb-ft (542-576 NŽm) in tightening sequence shown.

Raise vehicle with hydraulic jack, remove jack stand (15), and lower vehicle to ground.

Tighten six stud nuts (9) on front wheel 325-355 lb-ft (441-481 NŽm) and six stud nuts (9) on wheel

(10) 325-355 lb-fi (441-481 NŽm) in sequence shown.

9-5

Back to Top