TM-9-2320-361-20 - Page 667 of 1207

TM 9-2320-361-20

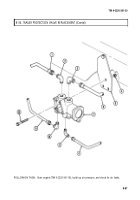

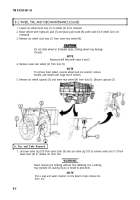

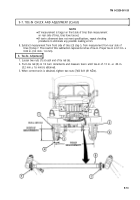

9-3. FRONT HUB AND DRUM MAINTENANCE

This task covers:

a. Removal

c. Lubrication

b. Cleaning and Inspection

d. Installation

INITIAL SETUP

APPLICABLE MODELS

All

MATERIALS/PARTS

Ten lockwashers

Six wheel studs

Ten screws

Inner bearing seal

GAA grease (Appendix C, Item 13)

REFERENCES (TM)

TM 9-2320-361-10

TM 9-2320-361-20P

TM 9-214

EQUIPMENT CONDITION

●

Front wheel (s) removed (para. 9-2) and rear

wheels chocked (TM 9-2320-361-10)

●

Front axle shaft flange removed (para. 7-10).

PERSONNEL REQUIRED

GENERAL SAFETY INSTRUCTIONS

Two

Keep fire extinguisher nearby when using

drycleaning solvent.

a. Removal

I

1. Bend back tab s on adjusting nut washer (13) and remove outer adjusting nut (14), adjusting nut

washer (13), and inner adjusting nut (12) from spindle (8).

2. Pull hub (2) and drum (10) with outer bearing (11) out about one inch. Push hub (2) and drum (10)

back, and remove outer bearing (11).

CAUTIO N

Do not slide hub and drum assembly over-threaded end of spindle, or

damage to equipment may result.

3. Remove hub (2) and drum (10) from spindle (8).

4. Remove ten nuts (15), lockwashers (16), and inspection cover (17). Discard lockwashers (16).

5.

Remove six wheel studs (9) from adapter (4) and hub (2). Discard studs (9).

6. Remove ten screws (5) from adapter (4) and drum (10). Discard screws (5).

7. Remove inner bearing (6) and seal (7) from spindle (8). Discard seal (7).

I

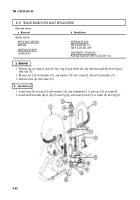

b. Cleaning and Inspection

I

1.

2.

3.

4.

5.

9-6

WARNIN G

Drycleaning solvent is flammable and will not be used near open

flame. Use only in well-ventilated places. Failure to do so may result

in injury to personnel.

Clean all hub (2) and drum (10) components with drycleaning solvent, and allow to air dry. Do not

use compressed air to dry bearings (6) or (11).

Inspect inner and outer bearings (6) and (11) (TM 9-214). If damaged, replace,

Inspect inner and outer bearing cups (1) and (3) (TM 9-214). If damaged, replace.

NOT E

Perform steps 4 and 5 only if bearings or bearing cups are to be replaced.

Remove inner and outer bearing cups (1) and (3) from hub (2) by tapping alternately on outer edge.

Press new inner and outer bearing cups (1) and (3) into hub (2). Ensure cups (1) and (3) are seated.

Back to Top