TM-9-2320-361-20 - Page 668 of 1207

TM 9-2320-361-20

I

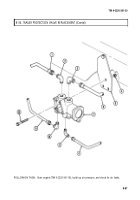

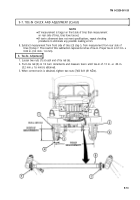

9-3. FRONT HUB AND DRUM MAINTENANCE (Contd)

6. Inspect hub (2) for cracks and breaks. Replace if cracked or broken.

7. Inspect drum (10) for deep grooves and cracks. Replace if broken. If grooved or scored, notify

supervisor.

8. Check adapter (4) for cracks or warps. Replace if cracked or warped.

c. Lubrication

1. Pack inner and outer bearings (6) and (11) with GAA grease (TM 9-214).

2. Apply light coat of GAA grease to rubber section of new inner bearing seal (7).

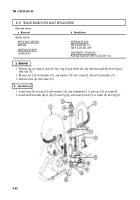

d. Installation

1.

2.

3.

4.

5.

6.

7.

8.

9.

Install seal (7) and inner bearing (6) on spindle (8).

Install adapter (4) on drum (10) with ten new screws (5).

Position hub (2) on adapter (4), aline inspection holes of hub (2) and drum (10), and install with six

new wheel studs (9).

Install inspection cover (17) (placed to cover inspection hole), ten new lockwashers (16), and

nuts (15) on new screws (5). Tighten nuts (15) 31-39 lb-ft (42-53 N·m).

CAUTION

Do not slide hub and drum assembly over threaded end of spindle,

or damage to equipment may result.

Install hub (2) and drum (10) on spindle (8).

Install outer bearing (11) in hub (2) and drum (10).

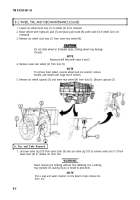

Check brake adjustment (para. 8-8).

Install inner adjusting nut (12) and front wheel on spindle (8).

Adjust outer bearing (11) (para. 9-5) and install adjusting nut washer (13) and outer adjusting nut

(14) on spindle (8). Bend tabs of adjusting nut washer (13) down,

FOLLOW-ON TASK Install front axle shaft flange (para. 7-10).

9-7

Back to Top