TM-9-2320-361-20 - Page 969 of 1207

TM 9-2320-361-20

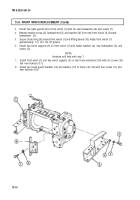

13-4. AUTOMATIC BRAKE TEST AND ADJUSTMENT

This task covers:

a. Testing

b. Adjustment

INITIAL SETUP:

APPLICABLE MODELS

EQUIPMENT CONDITION

All

Parking brake set (TM 9-2320-361-10).

PERSONNEL REQUIRED

GENERAL SAFETY INSTRUCTIONS

Two

Wear leather gloves when handling winch cable.

REFERENCES (TM)

Never stand between test vehicles during winching

procedures.

TM 9-2320-361-10

Assistant must remain in secondary vehicle.

Use hand throttle to control engine speed when

operating winch.

NOTE

Procedures for front winch and rear winch (M756A2) automatic

brake adjustment are the same. This procedure covers the front

winch testing and adjustment only.

1. Park test vehicle (1) at top of steep grade facing downhill and chock wheels (refer to

TM 9-2320-361-10).

2. Park secondary vehicle (2) at bottom of steep grade facing test vehicle (l).

WARNING

3.

4.

•Wear leather gloves when handling cable. Do not let cable run

through hands. Broken or rusty wires can cause injury to personnel.

•Never stand between test vehicles. Assistant must remain in

secondary vehicle to engage service brake if cable snaps or

automatic brake fails. Failure to do this may result in injury to

personnel.

CAUTION

Do not use front winch to pay out line loads greater than 3,000 lb

(1,362 kg) for any distance greater than 10 ft (3. 1 m). Damage to

equipment may result.

Pull out drum lock lever (4) and turn 90° clockwise to unlocked position. Unwind cable (5) and rig to

secondary vehicle (2).

Place secondary vehicle’s (2) transmission lever in neutral position. Disengage parking brake and

disengage front wheel drive lever if engaged.

WARNING

Never stand between test vehicles. Assistant must remain in

secondary vehicle to engage service brake if cable snaps or

automatic brake fails. Failure to do this may result in injury to

personnel.

Refer to TM 9-2320-361-10 for safe working loads.

5. Place winch drum clutch lever (3) in ENGAGE position.

13-4

Back to Top