TM-9-2320-361-34 - Page 235 of 764

TM 9-2320-361-34

10-4.

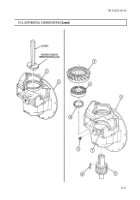

DIFFERENTIAL CARRIER REPAIR

(Contd)

NOTE

Lubricate all parts before assembly.

c.

Assembly

and Adjustment

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

10-18

Press pinion (9) on long end of shaft (10).

Press bearing (8) on hub of pinion (9).

Press bearing (11) on shaft (10).

Install shaft (10) in carrier (12) through opening in rear of carrier (12).

CAUTION

Use brass drift to insert bearing seats in carrier. Failure to do so

may result in damage to bearing seats.

Install bearing seats (7) and (13) on carrier (12) over bearings (8) and (11).

Using oil seal replacer and handle, install new oil seal (6) in front retainer (3) and new oil seal (6) in

rear retainer (5).

NOTE

Begin installation of shims with same thickness of shims on front

and rear retainer as removed during disassembly.

Aline holes in shims (4) with holes in retainers (3) and (5) and install shims (4), front retainer (3),

shims (4), and rear retainer (5) on carrier (12) with twelve washers (2) and screws (1). Tighten

screws (1) 65-85 lb-ft (88-115 N.m).

Wrap cable of bearing

preload

tester

around

shaft (10) and pull on tester until shaft (10) turns.

Proper bearing preload measurement is 7.44-34.04 lb (3.37-15.44 kg).

If bearing preload is correct, go to step 14.

Remove six screws (1), washers (2), and either retainer (3) or (5) from carrier (12).

NOTE

●

If measurement is more than limit, add a shim or use a thicker

shim.

●

If measurement is less than limit, remove a shim or use a thinner

shim.

Add or remove shims (4) as necessary.

Install retainer (3) or (5) on carrier (12) with six screws (1) and washers (2). Tighten screws (1) 65-85

lb-ft

(88-115 N.m).

Repeat step 8.

Remove six screws (1), washers (2), rear retainer (5), and shims (4) from carrier (12). Tie shims (4) to

retainer (6).

CAUTION

Use brass drift to remove shaft from carrier. Failure to do so may

result in damage to shaft.

NOTE

Do not remove bearings or pinion from shaft.

Remove bearing seat (7) and shaft (10) through hole in rear of carrier (12).

Back to Top