TM-9-2320-361-34 - Page 239 of 764

TM 9-2320-361-34

10-4.

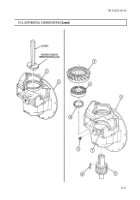

DIFFERENTIAL CARRIER REPAIR

(Contd)

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

10-22

Seat bearing seat

(17)

in bearing cage

(13).

NOTE

●

Begin

installation

of

shims

with same

thickness

of

shims

on

carrier

as removed during disassembly.

●

When

installing cage, bearings, and races, hold bevel gear in place

with soft spacers.

Aline holes in shims

(14)

with holes in bearing cage

(13)

and install shims

(14)

and bearing cage

(13)

on carrier

(16).

Using bearing replacer and arbor press, install bearings (18) and (20) and bearing seat (19) in

bearing cage

(13).

NOTE

Secure bevel gear with brass drift to prevent rotation.

Install plate (11) on helical pinion shaft

(15)

with two screws (12). Tighten screws

(12) 60-77

Ib-ft

(81-104

N.m).

Inspect carrier

(16)

for metal shavings. Clean carrier

(16)

of all shavings.

Aline holes in shims (8) with holes in bearing cover (9).

NOTE

.

Ensure even installation of bearing cage by evenly tightening

screws.

●

Begin

installation

with

same

thickness

of

shims on cage as

removed during disassembly.

Install shims (8) and bearing cover (9) on bearing cage

(13)

and carrier

(16)

with six screws (10).

Tighten screws (10) 65-85 lb-ft (88-115 N.m).

Wrap cable of bearing preload tester around bevel gear (1) and pull on tester until helical pinion

shaft (15) turns. Record measurement. Proper measurement is 2.4-7.1 lbs

(1.1-3.2 kg).

If bearing preload is correct, go to step 35.

Remove six screws (10) and bearing cover (9) from bearing cage (13) and carrier (16).

●

●

Add or remove

NOTE

If measurement in step 30 is more than limit, add a shim or use a

thicker shim.

If measurement in step 30 is less than limit, remove a shim or use

a thinner shim.

shims (8) as necessary.

Repeat steps 29 and 30.

Install shaft (2) and bearing seat (3) in carrier (16) through opening in rear of carrier (16).

Install shims (4) and retainer (5) on carrier

(16)

with six washers (6) and screws (7). Tighten

screws (7) 65-85 lb-ft (88-115 N.m).

Back to Top