TM-9-2320-361-34 - Page 247 of 764

TM 9-2320-361-34

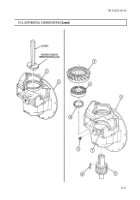

10-4. DIFFERENTIAL CARRIER REPAIR

(Contd)

NOTE

72.

73.

74.

75.

76.

77.

78.

79.

80.

81.

82.

83.

84.

10-30

Ensure wide end of taper on bearings faces case halves.

Press two bearings (1) on case halves (2).

If spider (9), thrust washers (11) and (3), pinion gears (10), and side gears (4) were not replaced,

proceed in step 77.

Install thrust washer (3) and side gear (4) in case half (2).

Install four pinion gears (10) and thrust washers (11) on spider (9).

Install thrust washer (3) and side gear (4) on spider (9).

Install spider (9), four pinion gears (10), side gear (4), four thrust washers (11), and thrust

washer (3) in case half (2).

NOTE

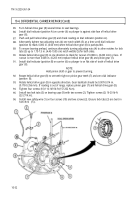

Aline marks on helical drive gear and case halves.

Install helical drive gear (5) on case half (2).

NOTE

Gear assembly should be in vise when tightening nuts.

Install other case half (2) on gear assembly with eight screws (12) and nuts (18). Tighten nuts (18)

130-167 lb (176-227 N.m). Aline holes in screws and nuts for installation of safety wire (17).

Install new safety wire (17) through eight nuts (18).

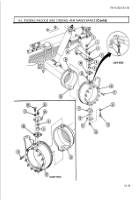

NOTE

●

Differential

gear is installed as an assembly with case halves and

bearings, thrust washers, side gears, spider, and pinion gears

attached to helical drive gear.

●

Install

bearing seats and adjusting nuts as tagged for

installation.

Install bearing seats (14) on bearings (1).

Install differential gear assembly (16) on carrier (15).

Position two adjusting nuts (13) on carrier (15) until seated against bearing seats (14).

Install two bearing caps (6) on carrier (15) with four washers (7) and screws (8). Finger tighten

screws (8), and alternately tighten two adjusting nuts (13) to contact bearing seats (14).

Back to Top