TM-9-2320-361-34 - Page 237 of 764

TM 9-2320-361-34

I

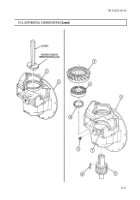

10-4. DIFFERENTIAL CARRIER REPAIR

(Contd)

16. Using bearing sleeve remover/replacer

and

screw, aline hole in sleeve (1) with setscrew (7) hole

in

carrier (2) and install sleeve (1) in carrier (2).

17. Install setscrew (7) in carrier (2) and sleeve (1).

NOTE

Install bearing with beveled side toward gear.

18. Press bearing (4) on bevel gear (3).

19. Install spacer (8) on bevel gear (3) until seated against bearing (4).

20.

CAUTION

Use brass drift

to install bevel gear. Failure to do so may result in

damage to gear.

Install bevel gear (3) in carrier (2) so bevel gear (3) rests in sleeve (1).

21. Install key (6) on helical pinion shaft (5).

CAUTION

22.

Use soft metal spacers to securely support bevel gear on sleeve

during installation. The bevel gear must not be able to move within

the housing. Failure to do so may result in damage to bevel gear

and/or housing.

NOTE

Ensure alinement of key in helical pinion shaft with keyway in

bevel gear.

Press pinion shaft (5) through carrier (2) into bevel gear (3).

10-20

Back to Top