TM-9-2320-361-34 - Page 353 of 764

TM9-2320-361-34

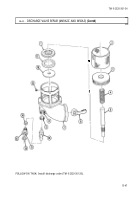

15-11. DISCHARGE VALVE REPAIR (M49A2C AND M50A3)

THIS TASK COVERS:

a. Disassembly

c.

Assembly

b. Cleaning

and Inspection

INITIAL SETUP

APPLICABLE MODELS

REFERENCES (TM)

M49A2C

and

M50A3

TM 9-2320-361-20

TEST EQUIPMENT

Micrometer (Appendix B, Item 3)

TOOLS

TM 9-2320-361-34P

EQUIPMENT CONDITION

Discharge valve removed (TM 9-2320-361-20).

General mechanic’s tool kit

GENERAL SAFETY INSTRUCTIONS

Eye protection must be worn when removing

or installing valve housing cover and during load

test of internal spring.

Keep fire extinguisher nearby when using

drycleaning solvent.

(Appendix B, Item 1)

●

Torque wrench, 1/2-in. dr. (Appendix B, Item 8)

Spring tester (Appendix B, Item 38)

MATERIALS/PARTS

.

Two seals (Appendix F, Item 222)

Packing (Appendix F, Item 179)

Disc (Appendix F, Item 24)

Antiseize tape (Appendix C, Item 25)

Rag (Appendix C, Item 16)

Drycleaning solvent (Appendix C, Item 24)

a. Disassembly

WARNING

Discharge

valve internal spring is compressed in cap. Eye

protection

must

be

worn when removing screws and cap from valve

housing. Failure to do this may cause injury to personnel.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Remove strainer (2) from valve housing (7).

Remove four setscrews (15) from valve housing (7).

Remove cap (3) and spring (4) from stem (5).

Remove stem (5) with holder (1), disc (17), and retainer (16) from valve housing (7).

Remove retainer (16), disc (17), and holder (1) from stem (5). Discard disc (17).

Remove nut (13) from bore (8) in valve housing (7).

Remove seals (11) and (14) from bore (12) in nut (13). Discard seals (11) and (14).

Remove cam stem (10) from cam (6) and valve housing (7).

Remove cam (6) from valve housing (7).

Remove packing (9) from bore (8) in valve housing (7). Discard packing (9).

15-42

Back to Top