TM-9-2320-361-34 - Page 605 of 764

TM 9-2320-361-34

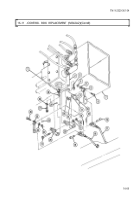

16-9.

HYDRAULIC CYLINDER REPAIR (M342A2)

‘

THIS TASK COVERS:

a.

Disassembly

c.

Assembly

b.

Cleaning and Inspection

INITIAL SETUP

APPLICABLE MODELS

MATERIALS/PARTS (CONTD)

M342A2

Three lockwashers (Appendix F, Item 125)

TOOLS

Three spacer rings (Appendix F, Item 206)

General mechanic’s tool kit

REFERENCES (TM)

(Appendix B, Item 1)

LO 9-2320-209-12-1

Inside micrometer (Appendix B, Item 16)

TM 9-2320-361-10

Torque wrench, 1/2-in. dr. (Appendix B, Item 7) TM 9-2320-361-34P

MATERIALS/PARTS

EQUIPMENT CONDITION

Cotter pin (Appendix F, Item 17)

Hydraulic cylinder removed (para. 16-8).

O-ring (Appendix F, Item 176)

Preformed packing (Appendix F, Item 182)

GENERAL SAFETY INSTRUCTIONS

Three piston rings (Appendix F, Item 205)

Wear eye protection when removing plugs. Plugs

Ten lockwashers (Appendix F, Item 145)

are under spring tension.

a.

Disassembly

1. Remove two adapters (6) and spacer rings (5) from hydraulic cylinder (1). Discard spacer rings (5).

2.

3.

4.

5.

6.

7,

8.

9.

10.

WARNING

Wear eye protection when removing plugs. Plugs are under spring

tension and may spring out during removal. Failure to wear eye

protection may result in injury to personnel.

Remove three plugs (4), springs (3), and balls (2) from hydraulic cylinder (1).

Remove plug (7), spacer ring (8), and fluid restrictor (9) from hydraulic cylinder (1). Discard spacer

ring (8).

Remove two setscrews (12) and pin (11) from hydraulic cylinder (1).

Remove fitting (10) from pin (11).

Remove three screws (23), lockwashers (22), gland (21), and preformed packing (20) from head (17).

Discard lockwashers (22) and preformed packing (20).

Remove ten screws (19), lockwashers (18), head (17), and O-ring (16) from hydraulic cylinder (1).

Discard lockwashers (18) and O-ring (16).

Remove piston rod (24) and piston (15) from hydraulic cylinder (1).

Remove three piston rings (25) from piston (15). Discard piston rings (25).

Remove cotter pin (13), nut (14), and piston (15) from piston rod (24). Discard cotter pin (13).

I

b.

Cleaning

and Inspection

1. For general cleaning instructions, refer to para. 2-8.

2. For general inspection instructions, refer to para. 2-9.

3. Inspect piston (15) for wear. Refer to table 16-4, M342A2 Hydraulic Cylinder Wear Limits, for

measurements. Replace piston (15) if worn past limit.

4. Inspect hydraulic cylinder(1) for wear. Refer to table 16-4, M342A2 Hydraulic Cylinder Wear

Limits, for measurements. Replace hydraulic cylinder (1) if worn past limit.

16-62

Back to Top