TM-9-2320-361-34 - Page 609 of 764

TM 9-2320-361-34

16-10.

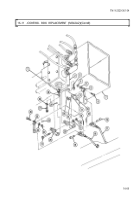

CONTROL VALVE REPLACEMENT (M342A2)

THIS TASK COVERS:

a.

Removal

b.

Installation

INITIAL SETUP

APPLICABLE MODELS

REFERENCES

(TM)

M342A2

TM 9-2320-361-34P

TOOLS

EQUIPMENT CONDITION

General mechanic’s tool kit

(Appendix B, Item 1)

●

Hydraulic pump removed (para. 16-12).

●

Control box removed (para. 16-11).

MATERIALS/PARTS

GENERAL SAFETY INSTRUCTIONS

Fifteen lockwashers (Appendix F, Item 125)

●

Wear eye protection when working with hydraulic

Two gaskets (Appendix F, Item 73)

hoses.

Gasket (Appendix F, Item 74)

●

Wear eye protection when removing plugs.

WARNING

Wear eye protection when working with hydraulic hoses. Fluid in

hoses may be under pressure. Failure to wear eye protection may

result in injury to personnel.

CAUTION

Cap or plug all openings immediately after disconnecting lines and

hoses to prevent contamination. Remove caps or plugs prior to

installation. Failure to do so may result in damage to equipment.

a. Removal

NOTE

●

Tag hydraulic lines for installation.

●

Have drainage container ready to catch hydraulic fluid.

1. Disconnect six hydraulic lines (5) from two manifolds (4).

2.

Remove seven screws (6), lockwashers (7), cover (8), gasket (10), valve (3), and gasket (2) from

hydraulic tank (9). Discard lockwashers (7) and gaskets (2) and (10).

3. Remove eight screws (1), lockwashers (13), adapter (12), and gasket (11) from valve (3). Discard

lockwashers (13) and gasket (11).

4. Remove two manifolds (4) from valve (3).

b. Installation

WARNING

Wear eye protection when removing plugs. Plugs are under spring

tension and may spring out during removal. Failure to wear eye

protection may result in injury to personnel.

1. Install two manifolds (4) on valve (3).

2. Install new gasket (11) and adapter (12) on valve (3) with eight new lockwashers (13) and screws (1).

3. Install new gasket (2) and valve (3) on hydraulic tank (9) with new gasket (10), cover (8), and seven

new lockwashers (7) and screws (6).

4. Connect

six hydraulic lines (5) on two manifolds (4).

16-66

Back to Top