TM-9-2320-361-34 - Page 617 of 764

TM 9-2320-361-34

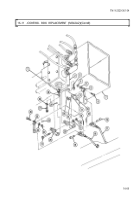

16-14. DUMP BODY SUBFRAME MAINTENANCE

THIS TASK COVERS:

a. Removal

c. Installation

b.

Inspection

INITIAL SETUP

APPLICABLE MODELS

REFERENCES

(TM)

M342A2

TM 9-2320-361-10

TOOLS

TM 9-2320-361-20

TM 9-2320-361-34P

1-1/8-in, socket, 3/4-in. dr. (Appendix B, Item 33)

1-1/4-in. socket, 3/4-in. dr. (Appendix B, Item 37)

EQUIPMENT CONDITION

Torque wrench, 3/4-in. dr. (Appendix B, Item 6)

●

Parking brake set (TM 9-2320-361-10).

Handle, socket wrench, 3/4-in. dr.

. Hydraulic pump propeller shaft removed

(Appendix B, Item 35)

(TM 9-2320-361-20).

Lifting device

●

Splash guards removed (TM 9-2320-361-20).

Sling

●

Dump body removed (para. 15-3).

MATERIALS/PARTS

Six locknuts (Appendix

F,

Item 105)

Four locknuts (Appendix F, Item 107)

PERSONNEL REQUIRED

Two

GENERAL SAFETY INSTRUCTIONS

All personnel must stand clear during lifting

operations.

a. Removal

1. Remove six locknuts (5) and screws (7) from two subframe brackets (4) and frame (6). Discard

2.

3.

4.

locknuts (5).

Remove four locknuts (11), washers (12), screws (9), eight keepers (13) and, springs (14), and eight

keepers (13) from two subframe brackets (1) and frame brackets (8). Discard locknuts (11).

Attach two chains to subframe channels (2). Attach lifting device to center two chains and remove

slack from chains.

Attach two guide lines to front and rear of subframe (3).

5.

6.

7.

8,

9.

10.

11.

WARNING

All personnel must stand clear during lifting operations. A swinging

or shifting load may cause injury to personnel.

NOTE

Assistant will help guide subframe during lifting operations.

Lift subframe (3) clear of frame sill (10) and frame (6) and place on wooden supports.

Disconnect lifting device tlom two chains.

Remove two chains from subframe channels (2).

Disconnect two guide lines from front and rear of subframe (3).

NOTE

Perform steps 9 through 11 if replacing subframe with new subframe.

Remove control valve (para. 16-10).

Remove hydraulic cylinders (para. 16-8).

Remove hydraulic safety latch (para. 16-13).

16-74

Back to Top