TM-9-2320-440-13-P - Page 507 of 1616

TM 9-2320-440-13&P

0051-7

0051

NOTE

Tighten hoses and fittings as required in WP 0158 or in each maintenance task. If a torque

wrench and crowsfoot are not available or cannot be used, use the following procedure.

1.

Install hose (1) on fitting (2).

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

NOTE

When turning effort increases, hose nut seat is in contact with fitting seat.

2.

Tighten hose (1) until seated on fitting (2).

NOTE

Alinement marks allow the mechanic to count the number of flats the hose has rotated

during tightening.

3.

Scribe alinement mark on hose (1) and fitting (2).

4.

Tighten hose nut (1) until mark on hose nut has rotated correct number of flats (refer to Table 1).

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

THAAD0582

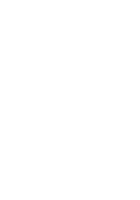

Table 1.

Recommended Flats Rotation.

THAAD0584

Dash No.

JIC 37-Degree

Flared Hose and Fitting

Machined Seat

SAE 45-Degree

Flared Hose and Fitting

Machined Seat

JIC 37-Degree

Flared Tube

-4

1 1/2 - 1 3/4

1 - 1 1/4

2 1/4 - 2 3/4

-5

1 - 1 1/2

1 - 1 1/4

2 1/4 - 2 3/4

-6

1 - 1 1/2

3/4 - 1

2 1/4 - 2 3/4

-8

1 1/4 - 1 3/4

1 - 1 1/4

2 1/4 - 2 3/4

-10

1 1/4 - 1 3/4

1 - 1 1/4

2 - 1/2

Back to Top