TM-9-2320-440-13-P - Page 509 of 1616

TM 9-2320-440-13&P

0051-9/(10 blank)

0051

2.

Check Torque.

Tighten nuts in a crisscross pattern using a torque wrench.

Apply 100% of final torque

value.

h.

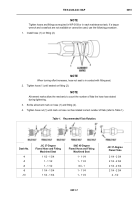

Pipe Thread Tightening Procedures.

WARNING

Adhesives, solvents, and sealing compounds can burn easily, can give off harmful

vapors, and are harmful to skin and clothing.

To avoid injury or death, keep away

from open fire and use in well-ventilated area.

If adhesive, solvent, and sealing

compound gets on skin or clothing, wash immediately with soap and water.

CAUTION

Use sealing compound sparingly and only on male threads.

Do not apply

compound on first two threads to avoid contamination of system from compound.

Do not apply compound to hose connections or fittings with preformed packings.

Damage to equipment may result.

1.

Coat threads of male fitting with sealing compound, sealant, or adhesive as indicated in each work

package.

2.

Position male fitting on female fitting.

Tighten only finger-tight.

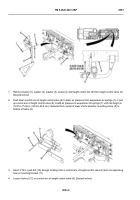

3.

Scribe alinement mark on both fittings.

CAUTION

•

If may be necessary to tighten fitting slightly more or less than 2 1/2 turns to match

position noted prior to removal.

Do not loosen fitting to arrive at proper position or

a leak may occur.

•

Overtightening may cause pipe fitting to deform and damage to the joining fitting,

flange, or component.

4.

Tighten male fitting 2 1/2 (3 maximum) full turns past hand-tight position.

PREPARATION FOR SHIPMENT OR STORAGE

a.

Refer to WP 0006 and TM 9-2320-325-14&P for preparation for shipment or storage information.

b.

While vehicle is in storage, perform the following tasks monthly:

1.

Coat MRP elevation cylinders and MRP rack locks with GAA grease (WP 0186, Item 18).

2.

Operate MRP elevation cylinders, MRP rack locks, outriggers, and LHS system (WP 0016).

END OF WORK PACKAGE

Back to Top