TM-9-2320-440-13-P - Page 536 of 1616

TM 9-2320-440-13&P

0056-2

0056

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

NOTE

•

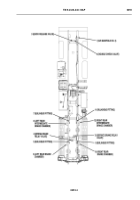

If difference between horizontal distance (A) and horizontal distance (B) is less than

0.25 in. (6.35 mm), axles are alined.

•

If distance between horizontal distance (A) and horizontal distance (B) is greater than

0.25 in. (6.35 mm), perform steps (7) through (11) to aline axles.

•

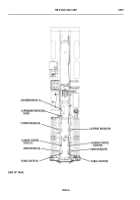

Raise chassis to raise axles from ground to aid in adding or removing shims.

7.

Remove two locknuts (6), four washers (7), two screws (8), lateral torque rod (9), bracket (10), shims (11), and

plate (12) from frame rail (3). Discard locknuts.

NOTE

Adding shims will decrease horizontal distance (B).

Subtracting shims will increase

horizontal distance (B).

8.

Remove or add shims (11) between bracket (10) and frame rail (3) so horizontal distance (B) is within 0.25 in.

(6.35 mm) of horizontal distance (A).

9.

Lubricate threads of two screws (8) with lubricating oil.

10. Install plate (12), shims (11), bracket (10), and lateral torque rod (9) on frame rail (3) with two screws (8), four

washers (7), and two locknuts (6).

Tighten locknuts (6) to 170 lb-ft (231 N•m).

11. Perform steps (5) through (10) until difference between horizontal distance (A) and horizontal distance (B) is

less than 0.25 in. (6.35 mm).

END OF TASK

FOLLOW-ON MAINTENANCE

1.

Remove wheel chocks (

END OF TASK

END OF WORK PACKAGE

THAAD0400

TM 9-2320-347-10)

Back to Top