TM-9-2330-227-14-P - Page 166 of 576

TM 9-2330-227-14&P

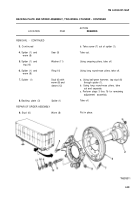

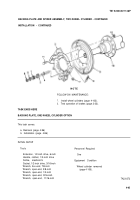

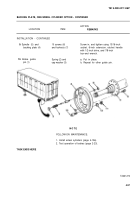

BRAKESHOE ASSEMBLIES, ONE-WHEEL CYLINDER OPTION

This task covers:

a. Removal (page 4-88)

c. Inspection/Replacement (page 4-90)

b. Cleaning (page 4-89)

d. Installation (page 4-90)

INITIAL SETUP

Tools

Materials/Parts

Brush, paint, 17/16-inch

Solvent, drycleaning, PD-680

Compressor unit, reciprocating air

(item 18, appendix E)

Gage, depth

Gun, blow, air

Personnel Required

Hammer, hand, ball-peen, 24b

Handle, ratchet, 1/2-inch drive

One

Mask, protective

Pliers, repair, brake

Equipment Condition

Pliers, slip-joint

Pliers, straight-jaw

Air reservoir drained (page 2-13).

Screwdriver, flat-tip, 3/16-inch

Hub and drum removed (page 4-143).

Socket, deep well, 1/2-inch drive,

7/16-inch

ACTION

LOCATION

ITEM

REMARKS

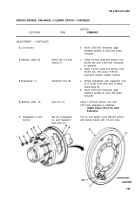

Brake linings contain asbestos fibers. Protective mask must be worn while performing

maintenance on brake linings. Failure to do so could result in injury or death to

personnel.

NOT E

Both sets of brakeshoes are removed, cleaned, inspected/replaced, and installed the

same way. This task is for one set; repeat for the other.

REMOVAL

1.

Two anchor

Two C-washers (2)

Using 3/16-inch flat-tip screwdriver and

pins (1)

and strap (3)

ball-peen hammer, take off washers (2)

and strap (3).

2.

Two retract

Brake retract

Using brake repair pliers, take off.

spring pins (4)

spring (5)

4-88

Back to Top