TM-9-2330-227-14-P - Page 168 of 576

TM 9-2330-227-14&P

BRAKESHOE ASSEMBLIES, ONE-WHEEL CYLINDER OPTION - CONTINUED

ACTION

LOCATION

ITEM

REMARKS

CLEANING - CONTINUED

6.

Continued

b. Using compressor and air gun, dry

with low pressure air.

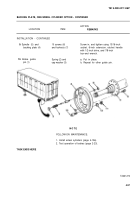

lNSPECTION/REPLACEMENT

WARNIN G

Worn brake linings could result in injury or death to personnel, When brake linings are

worn to within 0.0625-inch (1.59 mm) of rivets, they must be replaced.

NOT E

For more information on how to inspect parts, go to General Maintenance Instructions

(page 4-1).

7.

Brakeshoe

a. Look for glazed or loose condition.

linings (1)

b. Using depth gage, measure

lining thickness.

c. If glazed, loose, or worn, notify

Direct Support Maintenance.

8.

All parts

Look for bends, cracks, gouges, breaks

or severe signs of wear.

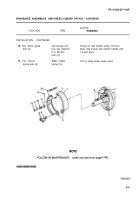

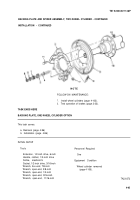

INSTALLATION

9.

Two brakeshoes (2)

Two retract spring

Put in.

pins (3)

10.

Two retract

Two cotter keys (4)

Put in, and spread using straight jaw

spring pins (3)

pliers.

11.

Two anchor pins

Two brakeshoes (2)

Put on, and slide into place.

(5) and brake

Be sure brakeshoes and brake

guide pins (6)

cylinders (7) line up properly.

12.

Two anchor

Strap (8) and two

Put on using slip-joint pliers and

pins (5)

C-washers (9)

ball-peen hammer.

4-90

Back to Top