TM-9-2330-247-14-P - Page 65 of 320

TM 9-2330-247-14&P

Table 4-2. Organizational Troubleshooting (Con’t).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Step 9.

Check master cylinder for damage or leaks,

If master cylinder is damaged or leaking, replace (para 4-35).

Step 10. Check hydraulic tubes and fittings for breaks, damage, or leaks.

If fittings are loose, tighten.

If hydraulic tubes and fittings are damaged, replace (para 4-37).

Step 11.

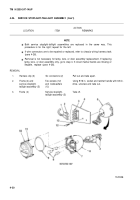

Remove hub and brakedrum (para 4-44). Check brake mechanism for broken or damaged parts.

If parts are broken or damaged, replace (para 4-32).

6.

BRAKES GRAB.

Step 1.

Check brake adjustment.

If brakes are out of adjustment, adjust (para 4-31).

Step 2.

Remove hub and brakedrum (para 4-44). Check for grease or dirt on brakeshoe linings.

If grease or dirt is present, replace brakeshoes (para 4-32).

Step 3.

Check for worn or loose brakeshoe linings.

If linings are worn to within 1/16 in. (1.6 mm) above rivets, or if linings are loose, replace

brakeshoes (para 4-32).

Step 4.

Check brakedrum for damage and signs of warpage.

If brakedrum is damaged, replace (para 4-44).

7.

HANDBRAKE DOES NOT WORK.

Step 1.

Check handbrake levers and cables for adequate lubrication or damage.

Lubricate handbrake levers (Chapter 3, Section l).

If handbrake cables are damaged, replace (para 4-30).

Step 2.

Check handbrake levers for proper operation or damage.

If handbrake levers are damaged, replace (para 4-30)

4-11

Back to Top