TM-9-2330-324-14-P - Page 188 of 350

TM 9-2330-324-14&P

0039 00-4

BRAKEDRUM, WHEEL HUB, AND WHEEL

0039 00

BEARING MAINTENANCE—Continued

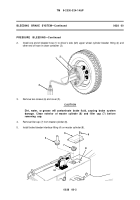

DISASSEMBLY—Continued

1.

Remove six nuts (11) and bolts (21) and remove adapter plate (18) and brakedrum (12) from hub

(10).

2.

Remove 18 nuts (14), flatwashers (13), bolts (17), and adapter plate (18) from brakedrum (12).

NOTE

Perform step 3 only if bearing cups (9) are being replaced. Bearing cups

should always be replaced when outer and inner wheel bearing cones ( 8

and 20) are replaced.

3.

Tap two bearing cups (9) out of hub (10).

4.

If damaged, remove six wheel bolts (22) from hub (10).

ASSEMBLY

NOTE

Right and left brakedrums/wheel hubs/wheel

bearings are assembled,

installed, and adjusted the same way. This procedure covers one side.

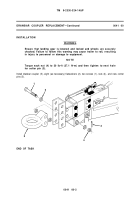

1.

If removed, install six wheel bolts (22) in hub (10).

2.

If removed, tap two bearing cups (9) into hub (10).

3.

Position adapter plate (18) on brakedrum (12), and install 18 bolts (17), flatwashers (13), and nuts

(14).

4.

Position adapter plate (18) and brakedrum (12) on hub (10) and install six bolts (21) and nuts (11).

NOTE

•

Refer to TM 9-214 for instructions for packing outer and inner wheel

bearing cones (8 and 20).

•

When installing spacer sleeve (16), ensure that flange faces inside of

trailer.

5.

Pack inner wheel bearing cone (20) with grease. Install inner wheel bearing cone, new oil seal (19),

and spacer sleeve (16) on hub (10).

INSTALLATION

1.

Install hub (10) and brakedrum (12) on axle (15).

2.

Pack outer wheel bearing cone (8) with grease. Install outer wheel bearing cone and inner adjusting

nut (7) on hub (10) and axle (15).

WHEEL BEARING ADJUSTMENT

1.

Tighten inner adjusting nut (7) while turning hub (10) and brakedrum (12) until drag is felt.

Back to Top