TM-9-2330-330-14-P - Page 188 of 1116

TM 9-2330-330-14&P

0034 00-12

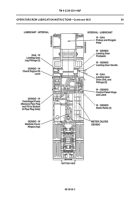

OPERATOR/CREW PREVENTIVE MAINTENANCE

CHECKS AND SERVICES (PMCS)—Continued

0034 00

Table 1. Operator/Crew PMCS—Continued.

ITEM NO.

INTERVAL

ITEM TO BE

INSPECTED

PROCEDURE

NOT FULLY MISSION

CAPABLE IF:

29—Continued

30

31

32

During

During

After

After

Control Panel

Emergency

Valve and Vent

Exterior of

semitrailer

Piping System

c.

Check gages for

proper operation as

follows

:

4.

Fuel pressure

gage should read

12 to 14 psi (83 to

97 kPa).

5.

Pump pressure

gage should read

no less than 30

psi (207 kPa) for

pump.

6.

Check filter/

separator gage.

d.

Check control panel

light for proper

operations.

Make sure all valves are

closed. Operate emergency

handle, and make sure

cable is actuating

emergency valve shutoff

lever fully and opens vent

on top of semitrailer.

a.

Walk around

semitrailer. Check for

loose, missing, or

damaged hardware.

b.

Check for evidence of

any leak

a.

Inspect all pipes for

dents or cracks.

b.

Drain water from N and

J valves.

Fuel pressure gage

reads below 12 or

above 14 psi

consistently.

Pump pressure gage is

not functioning

properly during

pumping operations.

Filter/separator gage

indicates 20 psi

(138 kPa) or higher.

Emergency valve

handle will not actuate

emergency valve

shutoff lever.

Hardware is loose,

missing, or damaged.

Any leak is evident.

Any pipe is damaged

to the extent that fuel

flow will be restricted.

Back to Top