TM-9-2330-335-14-P - Page 313 of 640

0067-7

TM 9-2330-335-14&P

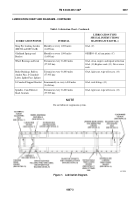

0067

COLD OPERATION

00067

For operation of equipment in extended cold temperatures below -15°F (-26°C), remove lubricants prescribed in the key for

temperatures above -15°F (-26°C). Re-lubricate with lubricants specified in the key for temperatures below -15°F (-26°C). If

OEA lubricant is required to meet the temperature changes prescribed in the key, OEA lubricant is to be used in place of OE/

HDO lubricant for all temperature ranges where OE/HDO lubricant is specified in the key.

END OF TASK

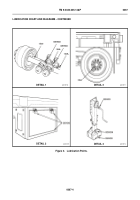

S-CAMSHAFT (SPECIFIC)

00067

1.

When the wheels and hubs are removed, place a light film of lubricant on cam roller follower shafts, journals,

and the top and bottom surface of the S-camshaft. Wipe off any excess lubricant.

2.

Observe the following warning and caution when lubricating automatic slack adjusters.

WARNING

Do not use any grease with Teflon, over 3% molysulfide content, or “white” grease in the

automatic slack adjusters. These lubricants will adversely affect the friction clutch and cause it not

to hold the adjustment, resulting in premature failure, injury to personnel, and damage to

equipment.

CAUTION

It is important not to overfill wheel-end cavity with lubricant. Do not exceed grease level indicated.

Also, make sure excess grease is wiped away since it can contaminate brake linings and cause poor

brake performance.

END OF TASK

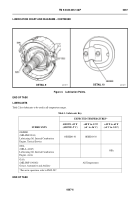

BEARINGS/HUBS

00067

1.

Pack bearing cones with grease by forcing grease into the cavities between rollers and cage from the large end of

the cone. The use of a pressure packer is recommended; otherwise pack the bearings by hand.

2.

Apply a light coat of grease to the spindle bearing journals and wipe off excess.

3.

Fill the hub cavity with grease to the outer cap’s smallest diameter.

4.

At the top of the spindle and as far back as possible, pump additional grease until it appears that the grease will run out.

Install the outer bearing cone quickly.

5.

Hub cavity will be filled approximately 1/3 full of grease (from the 4 to the 8 o’clock positions). This will involve

installation of approximately 1-1/2 lb (0.7 kg) of grease.

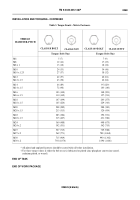

6.

Install the wheel retention hardware. Place a dab of grease across the face of the locknut for identification that hub cavity

has been greased if caps are not to be immediately installed.

CAUTION

Brush a thin layer of GAA on the inside of the hub cap. Do not cover vent with grease. Do not pack

the hub cap with grease. Do not coat the cap mounting flange with grease. Coating the cap vent

will result in seepage of lubricant and may clog the vent. Failure to comply can cause damage

to equipment.

7.

When brake shoes are replaced, apply an even coat of lubricant between contact face of anchor pin bushing, brake shoe

area, and spider faces. Coat anchor pin completely. Wipe off all excess grease.

END OF TASK

Back to Top