TM-9-2330-335-14-P - Page 315 of 640

TM 9-2330-335-14&P

0068-1

0068

ORGANIZATIONAL MAINTENANCE

-

TORQUE LIMITS

SCOPE

00068

This work package lists standard torque values and provides general information for applying torque. Special torque values

and tightening sequences are indicated in the maintenance procedures for applicable components.

GENERAL

00068

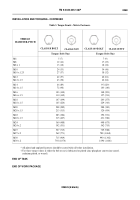

1.

Always use torque values listed in Tables 2 and 3 when a maintenance procedure does not give a specific torque

value.

a.

Table 2 provides torque limits for SAE standard fasteners.

b.

Table 3 provides torque limits for metric fasteners.

2.

Unless otherwise indicated, standard torque tolerance shall be

±

10%.

3.

Torque values listed are based on clean, dry threads. Reduce torque by 10% when engine oil is used as a lubricant. Reduce

torque by 20% if new plated capscrews are used.

CAUTION

If replacement capscrews are of higher grade than originally supplied, use torque specifications for

the original. This will prevent equipment damage due to overtorquing.

TIGHTENING METAL FASTENERS

00068

When torquing a fastener, select a wrench whose range fits the required torque value. A torque wrench is most accurate from

25 to 75% of its stated range. A wrench with a stated range of 0 to 100 lb-ft (0 to 136 Nm) will be most accurate from 25 to

75 lb-ft (34 to 102 Nm). The accuracy of readings will decrease as you approach 0 lb-ft or 100 lb-ft (136 Nm). The following

ranges are based on this principle.

Table 1. Metal Fasteners.

STATED RANGE

MOST EFFECTIVE RANGE

0 to 200 lb-in.

(0 to 23 Nm)

50 to 150 lb-in.

(6 to 17 Nm)

0 to 600 lb-ft

(0 to 813 Nm)

50 to 150 lb to ft

(68 to 610 Nm)

0 to 170 lb-ft

(0 to 230 Nm)

44 to 131 lb-ft

(60 to 178 Nm)

15 to 75 lb-ft

(20 to 102 Nm)

30 to 60 lb-ft

(41 to 81 Nm)

6

Back to Top