TM-9-2330-335-14-P - Page 307 of 640

0067-1

TM 9-2330-335-14&P

0067

ORGANIZATIONAL MAINTENANCE

-

LUBRICATION INSTRUCTIONS

GENERAL

00067

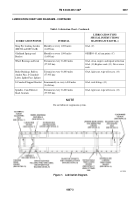

This work package contains lubrication instructions, showing location, intervals, and proper materials for lubricating the

semitrailer. These instructions are mandatory.

DETAILED LUBRICATION INFORMATION

00067

1.

Clean lubrication points, grease fittings, and surrounding areas before applying lubricant. Clean all lubrication

points after lubricating to prevent accumulation of foreign matter. Clean and lubricate bearings as specified in

TM 9-214.

2.

Maintain a record of vehicle lubrication and report any discrepancies noted during lubrication. Refer to DA PAM 750-8

for maintenance forms and procedures to record and report any findings.

SPECIFIC LUBRICATION INSTRUCTIONS

00067

1.

Keep all lubricants in closed containers and store in a clean, dry place away from extreme heat. Keep container

covers clean and do not allow dust, dirt, or other foreign material to mix with lubricants. Keep all lubrication

equipment clean and ready for use.

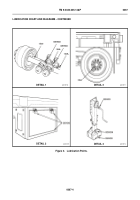

WARNING

Wipe excess lubricant from area of brake shoe linings to prevent any contamination of linings.

Replace linings that have been contaminated with lubricant. Failure to follow this warning may

cause brakes to malfunction, resulting in serious injury or death to personnel.

NOTE

Grease streaks on the outside or inside of the wheel may indicate overpacking of the grease, an

improperly installed grease seal, damage to the axle end, loose hardware, or gasket damage.

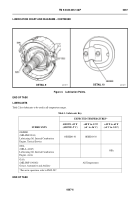

2.

Keep all external parts of equipment not requiring lubrication clean of lubricants.

3.

Refer to FM 9-207 for lubrication instructions in cold weather.

4.

After operation in mud, sandy, or dusty conditions, or when mission allows, clean and inspect all points of lubrication for

fouled lubricants. Change lubricants as required.

END OF TASK

8

Back to Top