TM-9-2330-335-14-P - Page 350 of 640

TM 9-2330-335-14&P

0075-2

0075

REMOVAL

00075

WARNING

•

Particles blown by compressed air are hazardous. DO NOT exceed 15 psi (103 kPa) nozzle pressure

when drying parts with compressed air. Use a maximum of 30 psi (207 kPa) when cleaning

components. DO NOT direct compressed air against human skin. To prevent injury, user must wear

protective goggles or face shield. Make sure air stream is directed away from user and other

personnel in the area. Failure to follow this warning may result in injury to personnel.

•

Wear welding mask, gloves, and apron when welding or using cutting torch. Failure to wear

adequate protective clothing may result in injury to personnel.

1.

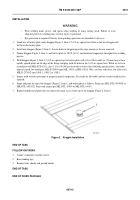

Measure from floor side of bulkhead (Figure 1, Item 1) and mark two straight lines on top metal plate

(Figure 1, Item 2) between main beams (Figure 1, Item 3) at locations shown.

2.

Using the air-arc process, make two straight cuts in top metal plate (Figure 1, Item 2) between main beams

(Figure 1, Item 3) at locations marked.

3.

Air-arc the existing welds securing the metal plate (Figure 1, Item 2) to the main beams (Figure 1, Item 3).

4.

Remove the cut out section of metal plate (Figure 1, Item 2) to gain access to top of kingpin.

5.

Using the air-arc process, remove the welds securing the kingpin (Figure 1, Item 4) 8-in.-round base to the bolster plate

(Figure 1, Item 5). A 300-amp welder is required along with a shop air supply of 90 psi (621 kPa). Care must be taken to

minimize damage to the bolster plate (Figure 1, Item 5).

6.

Remove and discard the kingpin (Figure 1, Item 4).

Figure 1.

Kingpin Replacement.

075

END OF TASK

447-0191

Back to Top